9F,Bldg.A Dongshengmingdu Plaza,No.21 Chaoyang East Road,Lianyungang Jiangsu,China +86-13951255589 [email protected]

Low permeability characteristics of microporous ceramic reference electrode: the cornerstone of precise measurement

In the field of electrochemical measurement, the reference electrode is a benchmark that provides a stable and known potential, and its performance directly determines the accuracy and reliability of the entire testing system. Among various types of reference electrodes, electrodes using microporous ceramics as liquid interface materials occupy a core position in long-term monitoring and harsh environmental applications due to their excellent * * low permeability characteristics * *. This' low-permeability 'design is the key technology for achieving long electrode life and high stability.

Core value and advantage of low permeability

1、 The connotation and physical mechanism of low permeability of microporous ceramics

Low permeability "has a precise definition here: it refers to the microporous ceramic membrane that allows ions to make small, controlled electrical contacts to maintain the conductivity of the electrochemical circuit, but at the same time greatly hinders rapid, high flow bidirectional convection and diffusion between the electrode filling solution (usually saturated KCl solution) and the external test solution.

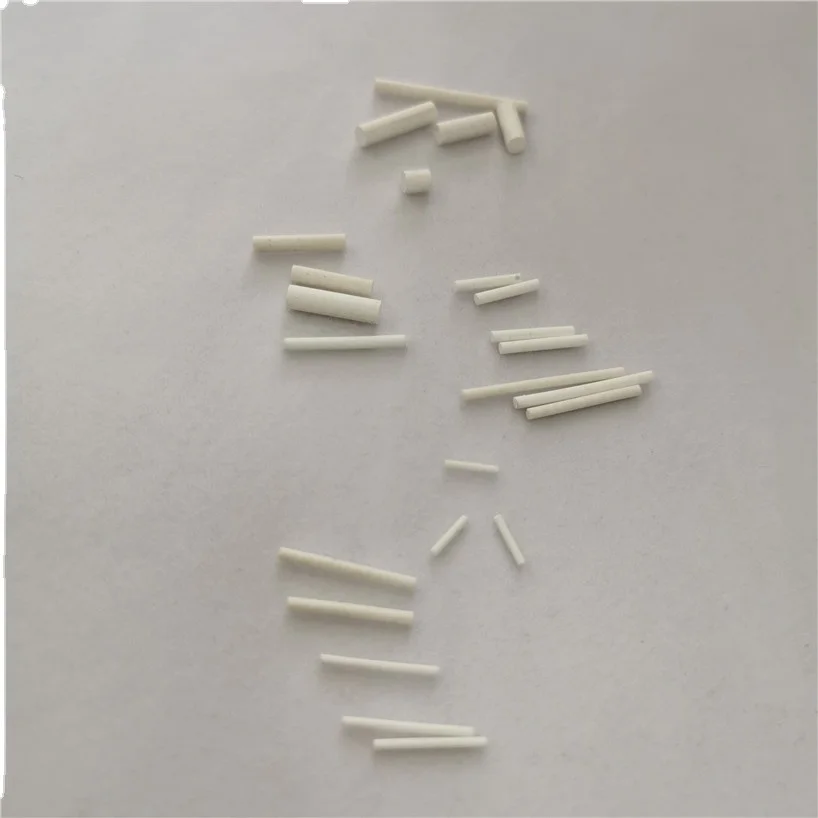

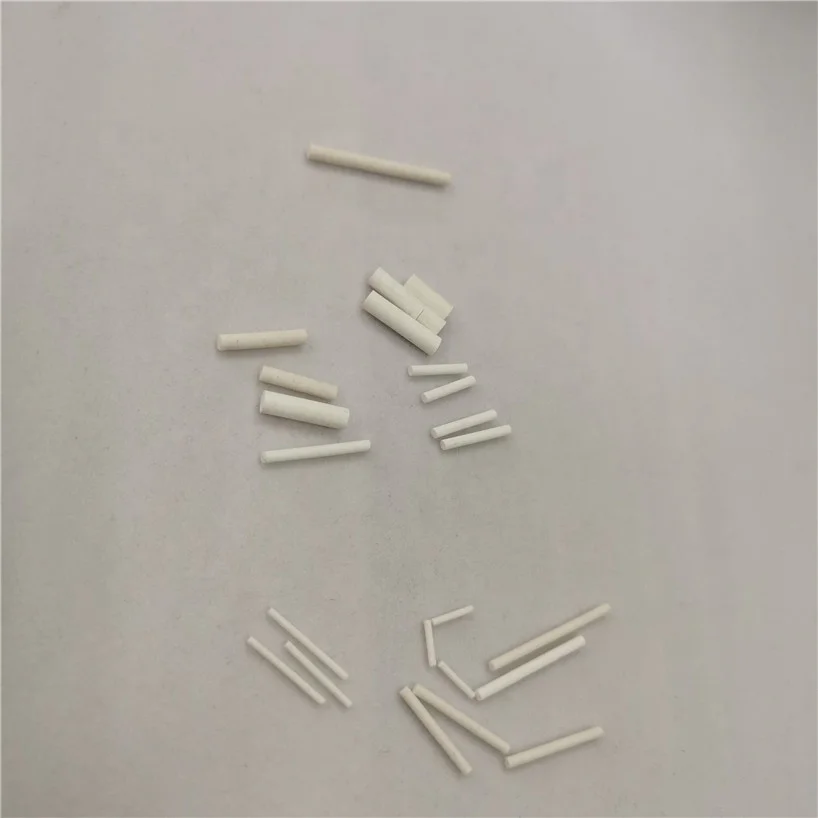

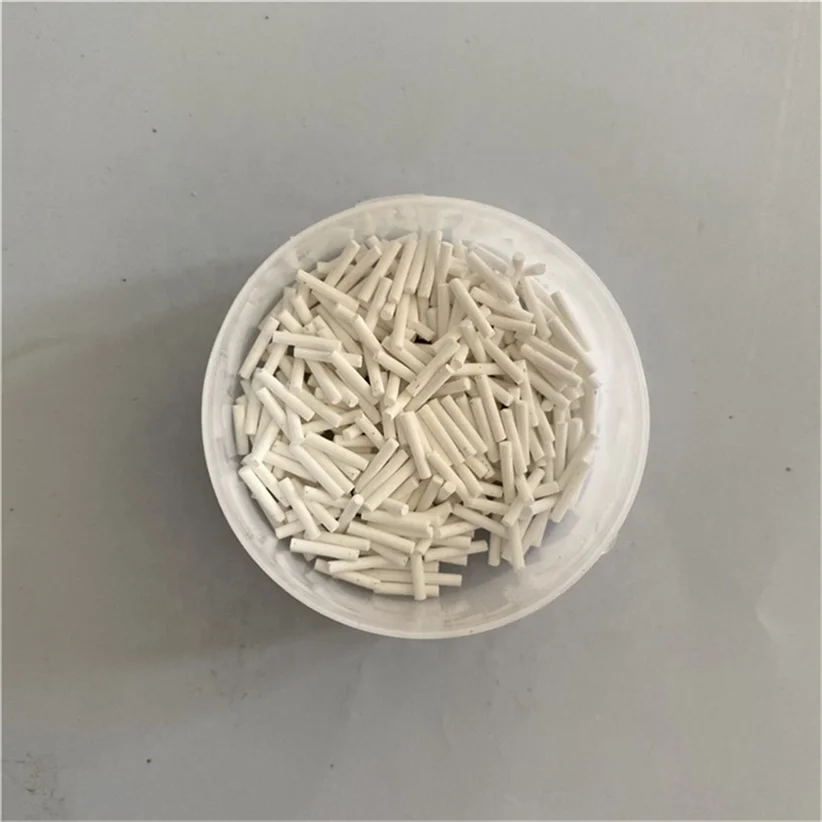

The implementation of this characteristic relies on the precise physical structure of microporous ceramic materials. Ceramic materials (such as alumina, zirconia, etc.) undergo special formulations and high-temperature sintering processes to form a rigid, robust, and porous structure with a large number of interconnected pores at the nanometer or submicron level. These pores constitute the electrochemical "liquid interface".

In short, microporous ceramic membranes play a role as "ion sieves" and "flow limiters" in physics, achieving a delicate balance between "conducting electrical signals" and "blocking solution exchange".

2、 The core advantage brought by low permeability

3、 Application and necessary trade-offs

Due to the above advantages, microporous ceramic reference electrodes have become the preferred solution for pH/potential measurement in easily contaminated media such as civil engineering (concrete and steel corrosion monitoring), geological exploration, environmental science (long-term water quality monitoring), as well as food and biotechnology.

However, every technology has its trade-offs. Low permeability brings an inherent technical challenge: high liquid interface resistance. The narrow pores mean that the ion migration path is obstructed, resulting in a high resistance value of the ceramic membrane itself (usually tens of thousands to hundreds of thousands of ohms). Therefore, when using such electrodes, it is necessary to use an electrochemical workstation or high impedance potentiometer with extremely high input impedance (usually requiring>10 ¹² Ω) for measurement, otherwise the signal will be severely attenuated, resulting in inaccurate readings, slow response, or even complete data failure.

In summary, the low permeability characteristics of microporous ceramic reference electrodes are not simply "non permeability", but a precise and controlled "limited permeability". Through its unique microstructure, it sacrifices some conductivity in exchange for unparalleled long-term stability, anti-interference ability, and measurement accuracy, becoming an indispensable technical guarantee for reliable electrochemical monitoring in harsh environments.

Technical Parameters Table

| Item | Infiltration Cup | Plant Water Absorbing Wick | Electrode Wick | Ceramic Wick | Scented Ceramic | |

| White alumina | Silicon Carbide | |||||

| Density(g/cm³) | 1.6-2.0 | 0.8-1.2 | 1.8-2.2 | 0.8-1.2 | 1.6-2.0 | 1.7-2.0 |

| Open Porosity Rate(%) | 30-40 | 50-60 | 20-30 | 40-60 | 30-45 | 35-40 |

| Porosity Rate(%) | 40-50 | 60-75 | 25-40 | 60-75 | 40-50 | 40-45 |

| Water Absorption(%) | 25-40 | 40-70 | 10-28 | 40-70 | 25-40 | 25-35 |

| Pore Size(μm) | 1-5 | 1-3 | 1-3 | 1-3 | 1-5 | 1-10 |