9F,Bldg.A Dongshengmingdu Plaza,No.21 Chaoyang East Road,Lianyungang Jiangsu,China +86-13951255589 [email protected]

Visible & IR Optical Glass Materials High-Performance Optical Glass Plate

An optical glass plate (or sheet) is a high-precision material manufactured from specially formulated glass to possess specific

and consistent properties for manipulating light. Its primary function is to transmit, reflect, refract, or modify light waves

in optical systems with minimal distortion or energy loss.

Unlike ordinary window glass, optical glass is characterized by its exceptional homogeneity, purity, and precisely controlled optical constants.

Key Characteristics:

The refractive index is a fundamental property, meticulously controlled during manufacturing for each glass type. It determines

how severely the glass bends light.

Also known as the constringence, this measures the material's dispersion (its tendency to separate light into its constituent

colors, like a prism).

A high Abbe number indicates low dispersion, which is critical for reducing chromatic aberration in lenses.

The refractive index is consistent throughout the entire volume of the glass plate. There are no striae, bubbles, or inclusions that

could distort the light wavefront.

Designed to have very high transmittance across specific wavelength ranges (e.g., visible, UV, or IR), with minimal absorption and scatter.

Surfaces can be polished to extreme smoothness and flatness (e.g., λ/10 flatness, 10-5 scratch-dig), which is critical for applications like laser windows, interferometry, and precise mirrors where any surface defect

would degrade performance.

Properties like hardness, density, and coefficient of thermal expansion are carefully considered for the intended

application to ensure stability and durability.

Common Types of Optical Glass

Generally has a lower refractive index and a high Abbe number (low dispersion). Used for elements where controlling chromatic aberration is key.

Contains lead or other heavy metals, giving it a higher refractive index and a lower Abbe number (high dispersion).

Often used in combination with crown glass to correct for chromatic aberration.

Primary Applications:

Optical glass plates are fundamental components in a vast array of devices and systems:

Key Advantages of the optical glass

The primary advantages of optical glass plates are their precision, consistency, and versatility.

They are the fundamental building blocks for creating high-performance optical systems where control over light is paramount, from simple camera lenses to

complex microscopes and lithography machines.

Controlled Refractive Index: Each type of optical glass has a precisely defined refractive index, allowing designers

to accurately calculate light paths in lenses and prisms.

Managed Dispersion (Abbe Number): The Abbe number is carefully specified, enabling the correction of

chromatic aberration (color fringing) in multi-element optical systems.

High Transmittance:They are formulated for maximum light transmission with minimal absorption

loss across specific spectral ranges (UV, Visible, or IR).Low Scatter and Inclusions:High homogeneity

ensures that light passes through without being scattered or distorted by internal imperfections, preserving image quality.

Surfaces can be polished to extreme smoothness and flatness (e.g., λ/10 flatness, 10-5 scratch-dig), which is critical for applications like laser windows, interferometry, and precise mirrors where any surface defect would degrade performance.

The chemical composition and refractive index are uniform throughout the entire volume of the glass.

This eliminates internal distortions and ensures consistent optical performance across the entire aperture.

Many optical glasses are designed to be highly resistant to staining,

weathering, and moisture, ensuring long-term durability and stable performance in harsh environments.

A wide range of glass types is available (e.g., Crown, Flint, Fused Silica) with different properties

(refractive index, Abbe number, density) to meet the exact requirements of virtually any optical system design.

Compared to plastics, optical glass offers greater hardness and rigidity, providing better resistance to

scratching and maintaining its shape under stress, which is vital for preserving optical alignment.

Technical specifications

|

Type |

Thickness (mm) |

light source A(2856k) |

light source(D65) |

||||

x |

y |

Y |

x |

y |

Y |

||

|

C2C14 KG2 HA-50 |

3 |

0.439 |

0.412 |

91.7 |

0.307 |

0.330 |

90.8 |

C3C16 KG3 HA-30 |

2 |

0.440 |

0.413 |

86.5 |

0.311 |

0.334 |

87.4 |

Type |

Thickness mm |

420nm |

500nm |

600nm |

700nm |

|

C2C14 KG2 HA-50 |

3 |

≥85.0 |

|

|

45.0~70.0 |

C3C16 KG3 HA-30 |

2 |

≥83.7 |

≥81.0 |

≥76.4 |

|

Type |

Thickness mm |

800nm |

900nm |

1000nm |

1060nm |

2200nm |

|

C2C14 KG2 HA-50 |

3 |

|

|

≤4.0 |

|

|

C3C16 KG3 HA-30 |

2 |

≤12.9 |

≤2.8 |

|

≤0.1 |

≤0.9 |

Type |

Stripe |

Stress |

|

C2C14 KG2 HA-50 |

3 |

4 |

C3C16 KG3 HA-30 |

3 |

4 |

Customized high purity polished transparent quartz glass plate for Semiconductor

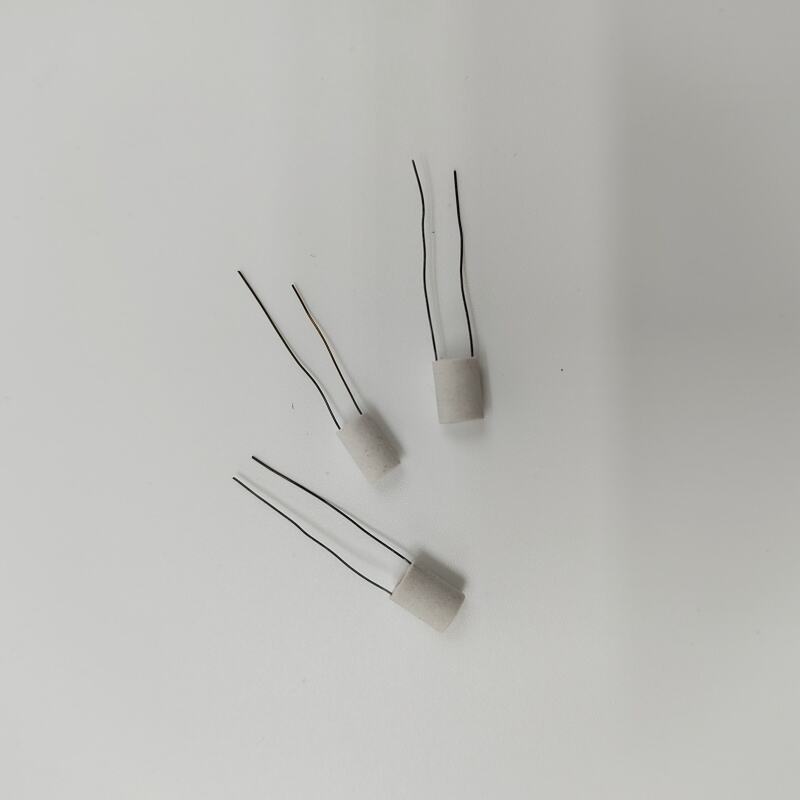

Porous Ceramic atomization Core heating element for medical and health equipment

Wooden Wick 7x73mm – High Absorption Ceramic Blended Mosquito Repellent Liquid Wick

High Purity 99% MgO Ceramic Spacers Magnesium Oxide Gasket for Thermocouple