9F,Bldg.A Dongshengmingdu Plaza,No.21 Chaoyang East Road,Lianyungang Jiangsu,China +86-13951255589 [email protected]

Magnesium Oxide Ceramic Spacers for High-Performance Industries. MgO ceramic, particularly high-purity MgO ceramic, is an advanced type of technical ceramic.

Magnesium Oxide Ceramic Spacers Features:

Magnesium oxide has an astonishingly high melting point of 2852°C, making it one of the highest melting points among all oxide ceramics. This characteristic directly dictates its capability to perform in ultra-high temperature environments. While most metals and other ceramic materials have softened or melted, MgO ceramic spacers can still maintain their structural integrity and functionality.

At elevated temperatures, the electrical resistance of materials typically decreases, leading to a deterioration of insulating properties. However, MgO ceramic maintains good electrical insulating properties even at high temperatures. Its high-temperature electrical resistivity is significantly higher than that of many common insulating materials, which is crucial for preventing electrical short circuits in high-temperature furnaces or equipment.

Although ceramic materials are generally considered brittle and sensitive to thermal shock, through optimized microstructure design and sintering processes, MgO ceramic can achieve satisfactory thermal shock resistance. This means it can withstand rapid and drastic temperature changes (fast heating and cooling) without cracking, a critical advantage for spacers used in cyclic heating processes.

MgO ceramic exhibits strong resistance to many molten metals and alkaline environments. It is not easily reactive with molten iron, steel, copper, aluminum, and other metals, making it an ideal material for crucibles, furnace linings, and support spacers in the metallurgical industry. However, it is important to note that its resistance to acidic environments is relatively weak, so the pH of the operating medium must be evaluated for specific applications.

Compared to alumina ceramic, MgO ceramic possesses a higher thermal conductivity. This property is beneficial in applications requiring rapid heat transfer or uniform heat dissipation, helping to reduce thermal gradients within components, thereby indirectly improving their thermal shock resistance and overall thermal efficiency.

MgO Gasket Advantages and Core Competitiveness

Building upon the aforementioned material properties, our Magnesium Oxide Ceramic Spacers deliver unparalleled value and solutions to our customers.

Our MgO ceramic spacers are engineered for extreme high-temperature environments. They can operate stably at continuous service temperatures ranging from 1600°C to 2200°C, with even higher short-term peak tolerance. This provides a reliable safety margin for processes like heat treatment, sintering, and crystal growth.

Due to their exceptional corrosion and wear resistance, MgO spacers significantly prolong the service life of furnace hearths, sintering equipment, and induction heating systems. They effectively resist erosion from furnace volatiles, molten metal splashing, and slag, reducing equipment downtime and maintenance costs.

At high temperatures, many materials experience creep or deformation. Our MgO ceramic spacers retain high mechanical strength and excellent dimensional stability under thermal load, ensuring precise positioning of supported workpieces and preventing product rejection or equipment failure due to spacer deformation.

We offer MgO ceramic spacers in various purity grades (from 95% to 99.5% and above). High-purity spacers feature extremely low levels of impurities and will not contaminate the precision materials being heated or molten metals, which is vital for the semiconductor, optical crystal growth, and high-end metallurgy industries.

We can manufacture MgO ceramic spacers in various shapes and sizes—including rounds, squares, tubes, and custom geometries—tailored to your specific requirements. Our advanced machining capabilities ensure spacers with precise tolerances and smooth surface finishes to meet the most demanding application needs.

Magnesium Oxide Ceramic Spacers Extensive Application Fields

The unique properties of Magnesium Oxide Ceramic Spacers make them key components in numerous high-tech and heavy industrial sectors.

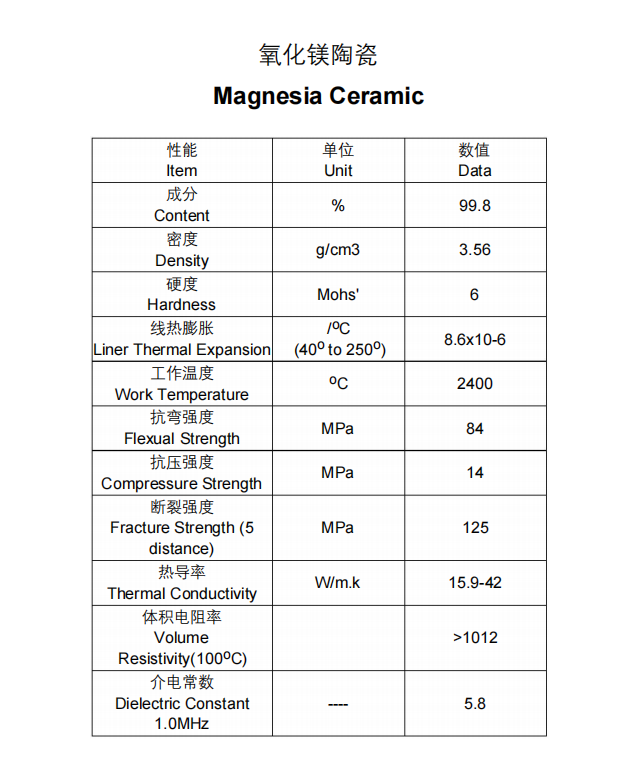

Technical specifications

Heat Resistant Alumina Al2O3 Ceramic Crucible for Lab Melting

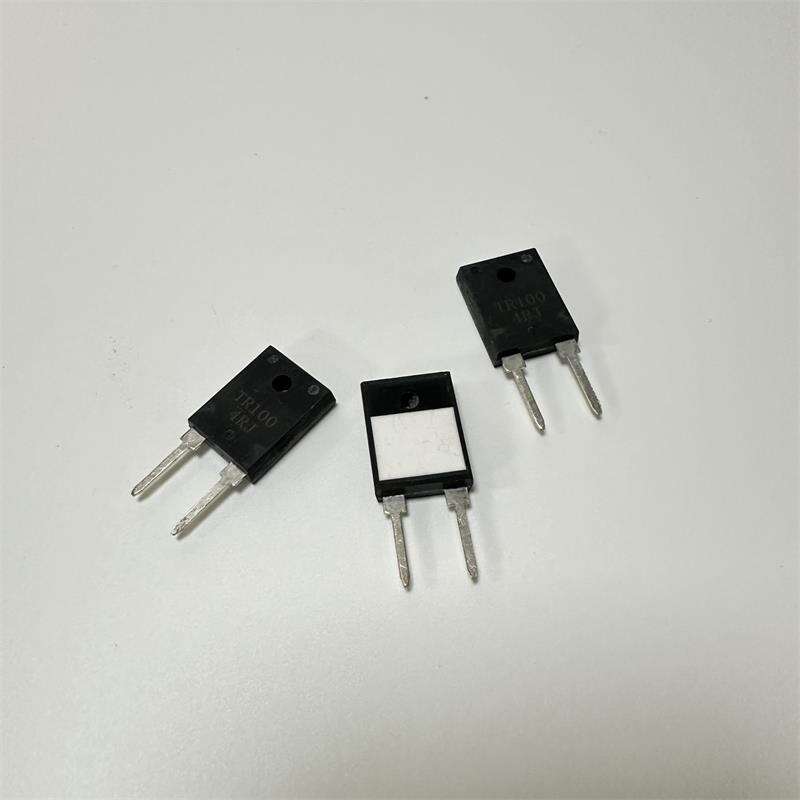

Non Inductive Thick Film High Frequency Resistor High Power Cylindrical High Voltage Resistor

High Temperature Heat Resistance Fused Quartz Glass Tube

Chemistry Laboratory Equipment 30mm 100mm 200mm Grey Natural Agate Mortar and Pestle Set