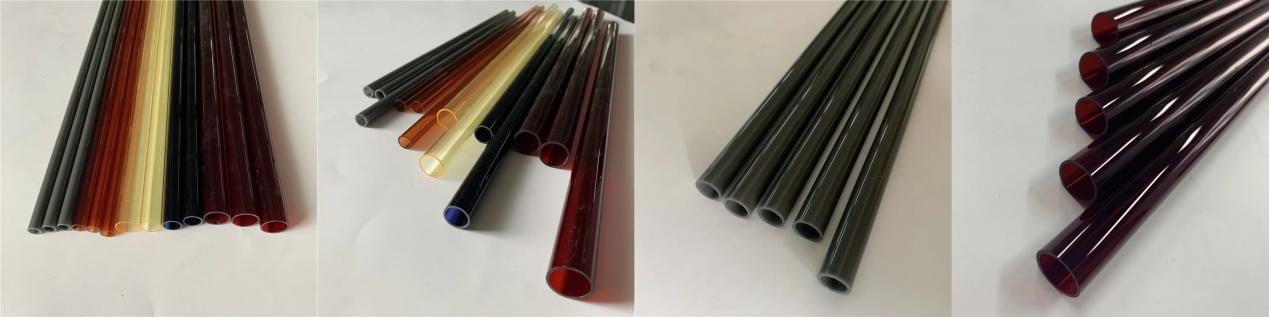

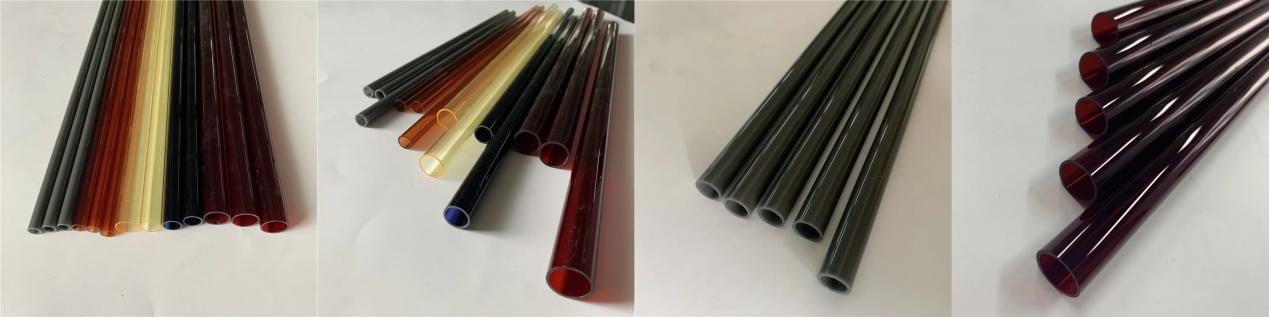

Manufacturing Process of Colored Quartz Tubes

Colored quartz tubes are primarily made from high-purity fused silica (SiO₂) and acquire their color through the introduction of specific metal oxide dopants during the manufacturing process. The color is not a surface coating but is integrated throughout the material. Here are the key processes:

The base material is high-purity natural quartz crystals or synthetic silicon tetrachloride (SiCl₄). The desired metal oxide colorants are prepared in precise powder form.

Common dopants include:

- Cobalt Oxide (Co₃O₄): For blue tubes.

- Chromium Oxide (Cr₂O₃): For green tubes.

- Manganese Oxide (Mn₂O₃): For purple/amethyst tubes.

- Titanium Oxide (TiO₂) & Iron Oxide (Fe₂O₃): Often used in combination for bronze/amber tubes (which also provide UV blocking).

- Gold (Au) or Selenium (Se): For red/pink shades.

- Doping and Homogenization

The precise amount of colorant powder is uniformly mixed with the crushed quartz feedstock. This step is critical to ensure consistent color distribution. In some processes, especially for synthetic quartz, the dopants can be introduced in gaseous form during chemical vapor deposition.

The doped quartz mixture is fed into a high-temperature furnace. There are two main melting methods:

- Electric Arc Melting: Used for natural quartz crystals. The mixture is melted in a carbon crucible at temperatures exceeding 2000°C.

- Chemical Vapor Deposition (CVD): Used for synthetic quartz. Gaseous compounds (like SiCl₄ and O₂) along with vaporized colorants are introduced into a high-temperature reactor, where they fuse and deposit layer-by-layer onto a rotating mandrel to form the tube.

During or after melting, the viscous quartz is shaped into tubes using processes like centrifugal casting (spinning a mold to form a hollow tube) or drawing (pulling molten quartz over a mandrel).

The formed tubes are slowly cooled in a controlled annealing furnace. This relieves internal thermal stress, prevents cracking, and stabilizes the color centers formed by the dopants.

After annealing, the tubes are cut to length, and the ends may be flame-polished or ground to achieve the required dimensional tolerance and surface finish. They are then thoroughly cleaned.

Key Characteristics of the Process:

-

Permanent Color: The color is inherent and will not fade under high temperatures or UV exposure.

-

High-Temperature Stability: Colored quartz tubes retain the excellent thermal properties of pure quartz.

-

Dopant-Dependent Properties: Some colorants (e.g., titanium/iron for amber) intentionally add functionality like UV absorption.

This process results in durable, high-performance colored quartz tubes used inlighting (e.g., halogen lamps, UV lamps), laboratory equipment, semiconductor tools, and decorative applications.

Advantage

Colored quartz tubes inherit the fundamental benefits of pure fused silica while adding specialized functionality through their integrated colorants. Their primary advantages include:

- Selective Light Transmission/Filtration: This is the core advantage. Different colors absorb and transmit specific wavelengths of light.

- Example: Amber/brown tubes block ultraviolet (UV) and short-wavelength blue light, while transmitting visible light. Deep violet "Wood's glass" tubes transmit long-wave UV-A but block visible light.

- Enhanced Durability & Stability: The color is not a surface coating but is fused into the quartz matrix. This makes it:

- Non-fading: Resistant to fading from intense UV, visible light, or heat.

- Scratch-resistant: The color cannot be scratched off.

- Chemically inert: Maintains excellent chemical resistance against most acids and solvents.

- High Thermal Performance: Like clear quartz, colored tubes exhibit:

- Extreme Heat Resistance: Withstanding temperatures up to 1000-1100°C.

- Low Thermal Expansion: Excellent thermal shock resistance.

- High Purity: Prevents contamination in sensitive processes.

- Visual Indication & Safety: Color provides immediate visual identification of light source type, wavelength, or process, enhancing safety and operational clarity.

Major Applications

Based on their functional advantages, colored quartz tubes are critical in several industries:

- Halogen & Incandescent Lamps: Amber or red tubes are used in heating lamps, insect traps, and darkroom safelights.

- UV Lamps:

- Blacklight Blue (BLB): Deep violet tubes used in entertainment, fluorescence inspection, and counterfeit detection.

- Germicidal: Special formulations that allow optimal transmission of UV-C (254 nm) for disinfection.

- Specialty Signaling & Decorative Lighting: For colored filters in high-temperature fixtures.

- Semiconductor & Photovoltaic Manufacturing

- Diffusion & Oxidation Furnaces: Used as process tubes. Color can sometimes indicate tube type or doping.

- UV Curing & Photolithography: Tubes that transmit specific UV wavelengths for curing polymers or exposing photoresists.

- Laboratory & Scientific Equipment

- UV-Vis Spectroscopy: As sample cells or filters.

- Photochemical Reactors: Tubes that allow specific actinic wavelengths to drive chemical reactions.

- Environmental Chambers: As viewports with specific spectral filtering.

- Industrial & Medical Processes

- Water & Air Purification: UV-transmitting tubes in disinfection systems.

- Medical Devices: Used in phototherapy lamps for treating jaundice (blue light) or skin conditions (UV light).

- Food & Beverage Processing: For UV treatment or inspection systems.

- Decorative & Architectural

- High-End Lighting Fixtures: For permanent, heat-resistant colored elements.

- Art Installations: Utilizing the durability and luminous properties of the material.

Technical specifications

Property Content |

Property Index |

Density |

2.2×103kg/cm³ |

Strength |

570KHN100 |

Tensile Strength |

4.8×107Pa(N/㎡) |

Compression Strength |

>1.1×109Pa |

Coefficient of Thermal Expansion |

5.5×10-7cm/cm℃ |

Thermal Conductivity |

1.4W/m℃ |

Specific Heat |

660J/kg℃ |

Softening Point |

1630℃ |

Annealing Point |

1180℃ |