Comprehensive analysis of PET cotton filtration and oil storage cotton

Basic performance

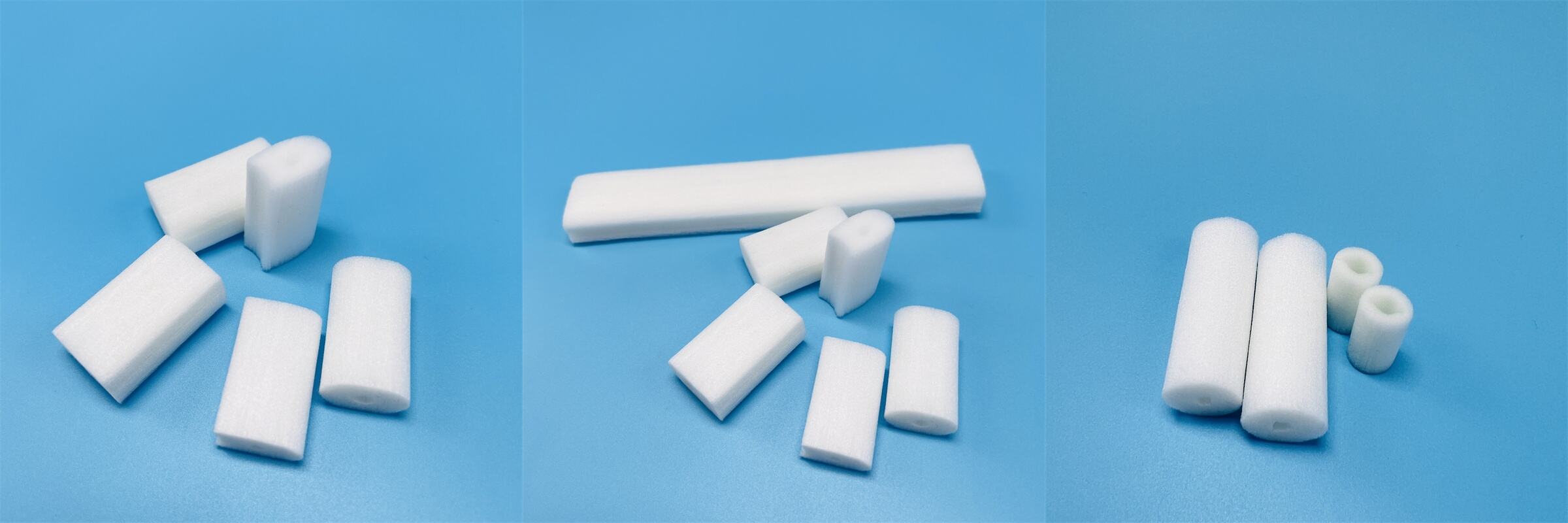

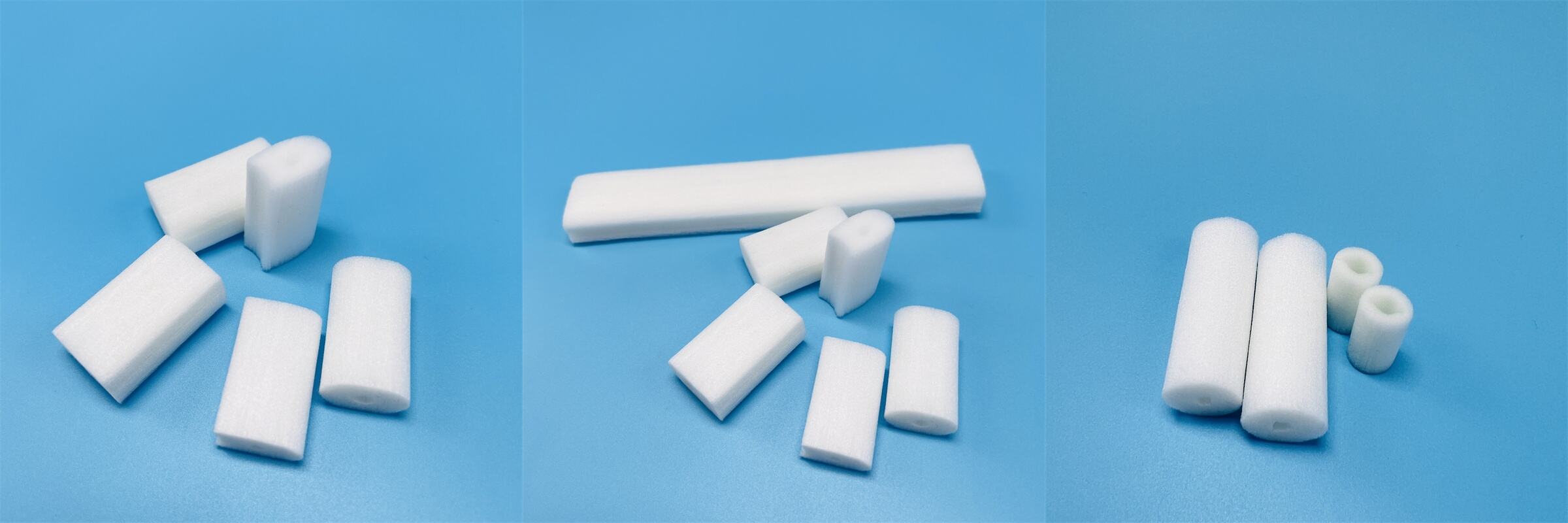

PET cotton is a three-dimensional mesh structure material made from polyester fibers through processes such as needle punching, melt spraying, or winding. As a filter oil storage cotton, its core performance is reflected in:

- Fiber structure: The fiber fineness, length, and arrangement can be adjusted to form intricate channels, which can effectively intercept solid particles and allow oil to pass through and be stored smoothly.

- Porosity and permeability: With high porosity (usually>90%), it provides sufficient storage space while maintaining low airflow resistance.

- Oil and water repellency: PET material itself has excellent oil affinity, which can quickly adsorb and retain lubricating oil, while repelling moisture and preventing emulsification.

- Mechanical performance: It has high tensile strength and toughness, can withstand the fluctuation of air pressure and the impact of oil flow in the system, and is not easily damaged or deformed.

Core Features

- Efficient oil dust separation: Through various mechanisms such as direct interception, inertial impact, diffusion effect, and gravity settling, solid particles (such as dust and worn metal shavings) in compressed air are efficiently captured and contained.

- Deep oil storage and uniform oil return: The three-dimensional network structure resembles a "storage tank" that can evenly store and distribute oil within the fibers. Under the action of airflow, the oil can be slowly and evenly released back into the system, ensuring continuous lubrication.

- Good structural stability: resistant to fatigue, able to maintain structural stability under long-term cyclic use and pressure changes, avoiding secondary pollution caused by fiber shedding.

- Chemical compatibility: It has good chemical stability for most mineral oils, synthetic lubricants, and hydraulic oils, and is not prone to degradation or chemical reactions.

Main advantages

- The balance between high filtration accuracy and long lifespan: Compared to materials such as metal wire mesh, PET cotton can achieve higher initial filtration accuracy (up to 1-3 microns), and due to its strong dust and oil storage capacity, the pressure difference rises slowly, and the service life is significantly extended.

- Excellent oil return performance: This is one of its most critical advantages. Effective oil return can reduce fuel consumption, lower operating costs, and prevent oil from being discharged with compressed air, causing environmental pollution and downstream equipment pollution.

- Protecting key components: By effectively removing particulate pollutants, it provides crucial protection for precision core components such as bearings, rotors, and cylinders, reducing wear and extending the lifespan of the host.

- High comprehensive cost-effectiveness: Although the cost per unit may be higher than that of a simple filter, its long replacement cycle, fuel saving benefits, low equipment failure rate, and low maintenance costs make its total cost of ownership (TCO) highly competitive.

- Flexible design and application: The fiber ratio, density, thickness, and shape can be flexibly adjusted according to the operating conditions (flow rate, pressure, oil) of different equipment (such as screw air compressors, vacuum pumps) to achieve customized performance.

Typical application areas

PET cotton filter oil storage cotton is the core component of oil and gas separation and intake filtration, mainly used for:

- Air compressor: used for oil and gas separator filter element (to separate lubricating oil from compressed air) and intake filter (to filter the inhaled air). This is its largest application market.

- Vacuum pump: used for oil lubrication rotary vane vacuum pump and screw vacuum pump oil gas separation filter element, to prevent pump oil from being extracted and polluting downstream processes or vacuum environment.

- Automobiles and internal combustion engines: used in engine crankcase ventilation systems (oil and gas separators/PCV filters) to separate and recover engine oil from blow by gases, reducing carbon deposits in the intake system and oil consumption.

- Gas turbines and turbomachinery: Used for the return oil filter of the lubrication system to ensure the cleanliness of the lubricating oil returned to the oil tank.

- Industrial gearboxes and hydraulic systems: as lubricating oil filters or respirators, they filter out particulate impurities while maintaining lubrication.

Summary

The success of PET cotton filtering oil storage cotton lies in its perfect balance of the three functions of "filtration", "oil storage", and "oil return". It is not a simple "sieve", but a dynamic and functionally integrated oil management system.

Its high cost-effectiveness, reliable performance, and wide applicability make it the mainstream choice in mid to high end industrial filtration applications. When selecting, it is necessary to choose or customize the appropriate PET cotton filter material density, thickness, and processing technology based on the specific operating conditions of the equipment, the type of oil, and the requirements for accuracy and lifespan, in order to maximize its efficiency.

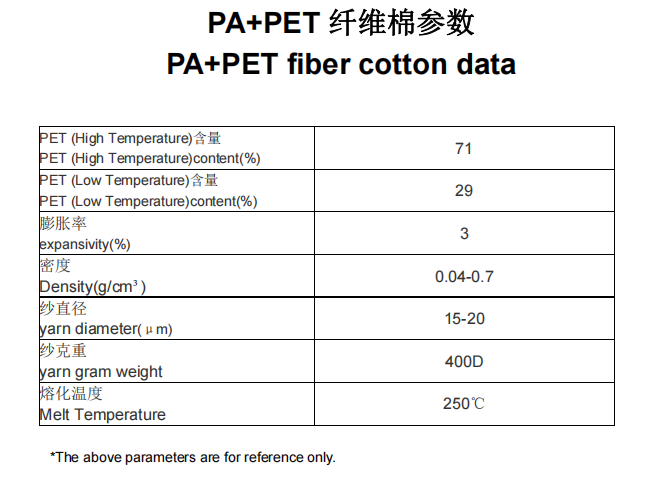

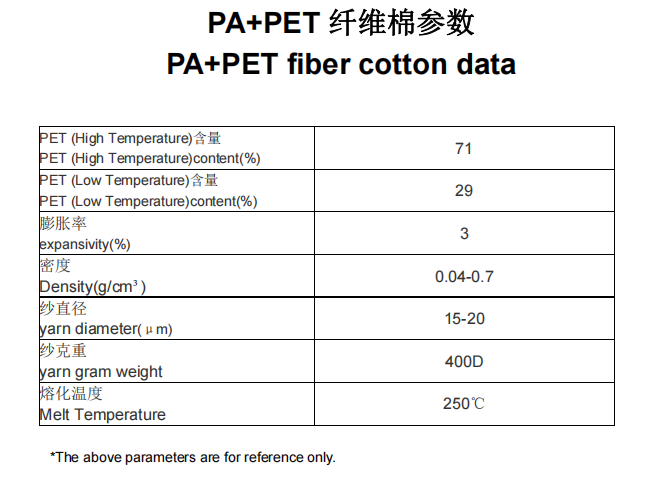

Technical specifications