Silica Quartz Glass Rod:

Clear quartz glass rod long time working temperature is 1100 degree and short time working temperature is 1200 degree. And the quartz glass rod purity is above 99.9% and with high UV transmission at 254nm.

Production Process and Flow of Quartz Glass Rods

- Raw Material Preparation:

High-purity natural quartz crystals or synthetic silica(SiO2 content typically >99.9%) are selected as raw materials. The material is carefully cleaned and crushed to the required size for processing.

The purified quartz material is loaded into a high-temperature furnace(often an electric or vacuum furnace). It is heated to temperatures exceeding 2000°C to become fully molten, forming a homogeneous, bubble-free silica melt.

The molten silica is then shaped into rods using one of two primary methods:

Drawing Method: The melt is drawn vertically or horizontally through precision dies or rollers to form continuous rods of specific diameters.

Molding/Pressing Method: The viscous melt is transferred into graphite or ceramic molds and pressed to form rods of predetermined dimensions.

The formed quartz glass rods are transferred to an annealing furnace.They are gradually heated to a defined temperature (typically between 1000-1200°C) and held to relieve internal thermal stresses. Subsequently, they are cooled at an extremely slow, controlled rate to prevent stress buildup and cracking, ensuring structural stability.

- Precision Processing (Secondary Processing):

The annealed rods undergo several finishing steps:

- Dimensioning: They are cut to precise customer lengths using diamond saws or laser cutters.

- Surface Finishing: The rods are ground (centerless grinding) and polished to achieve the required surface smoothness, diameter tolerance, and optical clarity (if needed). For some applications, the ends are fire-polished.

- Quality Inspection & Cleaning:

Each rod undergoes rigorous inspection for:

- Dimensions: Diameter, length, and straightness.

- Optical Properties: Transparency, bubble/inclusion content, and homogeneity (for optical grades).

- Physical/Chemical Properties: OH⁻ ion content, thermal stability, and purity.

- Defects: Cracks, chips, or surface scratches.

After inspection,rods are thoroughly cleaned in ultrasonic baths with high-purity solvents (e.g., acids, deionized water) to remove contaminants.

The finished quartz glass rods are carefully packaged in clean,protective materials (often plastic sleeves or foam) and labeled according to specifications. They are stored in a clean, dry environment to prevent contamination before shipment.

Key Process Characteristics:

- High-Temperature Processing: Requires specialized furnaces resistant to silica corrosion.

- Cleanroom Environment: Critical for optical and semiconductor-grade rods to prevent impurity introduction.

- Precision Control: Tight control over temperature, drawing/pressing speed, and cooling rates is essential for consistent quality.

- Material Purity: The entire process is designed to maintain the extremely high purity of the starting material.

The advantages of quartz glass rods include:

- Exceptional Thermal Stability: They can withstand extremely high temperatures and have a very low coefficient of thermal expansion, meaning they resist cracking under rapid temperature changes.

- High Purity and Chemical Inertness: They are highly resistant to corrosion from most acids, salts, and chemicals, ensuring product purity in sensitive processes.

-

Excellent Optical Properties: quartz glass rods offer high transparency across a wide spectral range, from ultraviolet (UV) to infrared (IR) light.

- Superior Electrical Insulation: They possess excellent dielectric strength and are reliable insulators even at high temperatures.

- High Mechanical Strength & Durability: They are rigid and have good resistance to wear and deformation compared to other glass materials.

Applications

The resulting quartz glass rods are used in optical fibers, semiconductor manufacturing equipment, lighting (halogen lamps, UV lamps), laboratory ware, and precision instruments due to their high purity, excellent thermal stability, and superior optical properties.

Quartz glass rods are indispensable components across multiple high-tech industries due to their unique properties.

- Optics & Photonics: Used as light guides, optical fibers (preforms), lenses, and windows in lasers, spectrophotometers, and UV lighting systems due to exceptional light transmission.

- Semiconductor Manufacturing: Critical for wafer carriers (boats), furnace tubes, and diffusion components in high-temperature processes where purity and thermal stability are paramount.

- Laboratory & Analytical Instruments: Serve as sample holders, stir rods, and reaction vessels in corrosive or high-temperature chemical analyses (e.g., ICP-MS, chromatography).

- High-Temperature Industrial Processing: Employed in thermal processing equipment for metal heating, glassworking, and as sight glasses in high-temperature furnaces.

- Lighting Industry: Used as envelopes or supports for halogen lamps, UV lamps, and other high-intensity discharge lamps where transparency and heat resistance are essential.

- Communications: Form the core material of optical fiber preforms, which are drawn into fibers for telecommunications and data transmission.

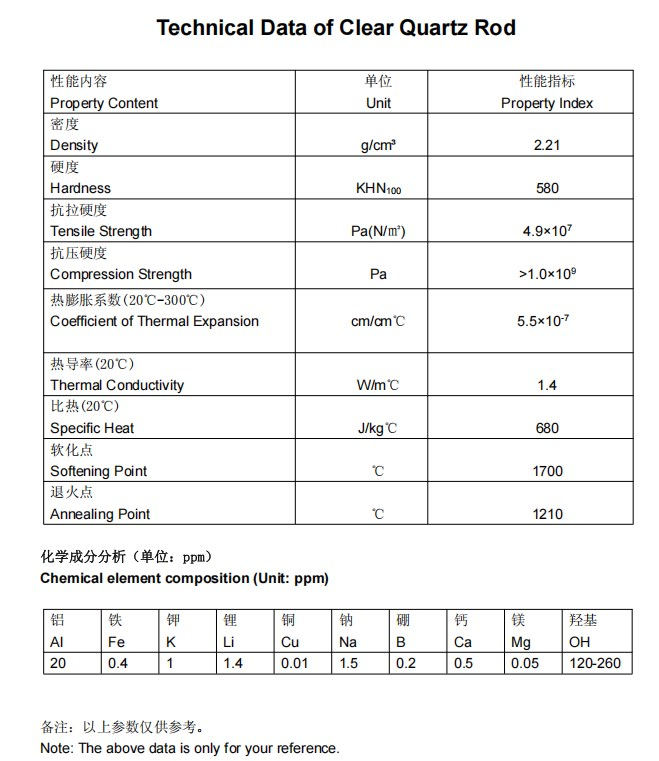

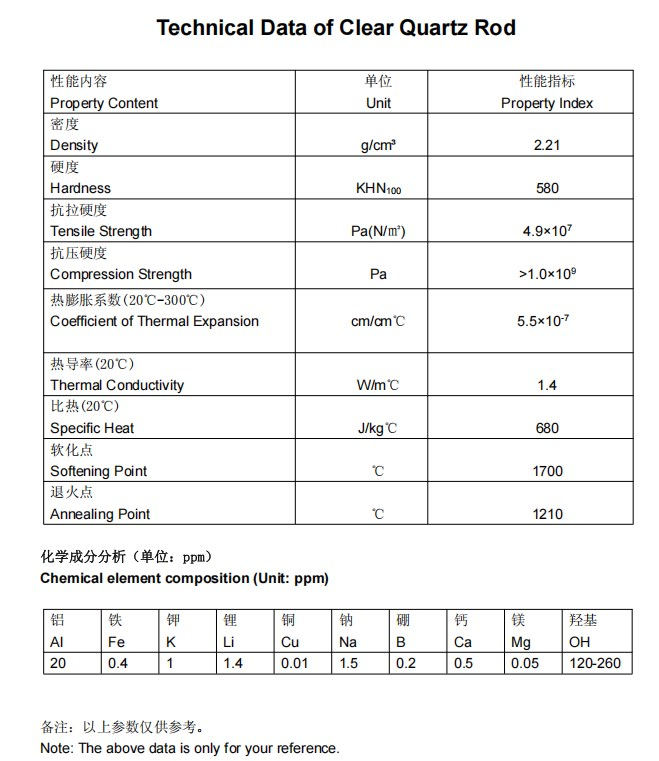

Technical specifications