9F,Bldg.A Dongshengmingdu Plaza,No.21 Chaoyang East Road,Lianyungang Jiangsu,China +86-13951255589 [email protected]

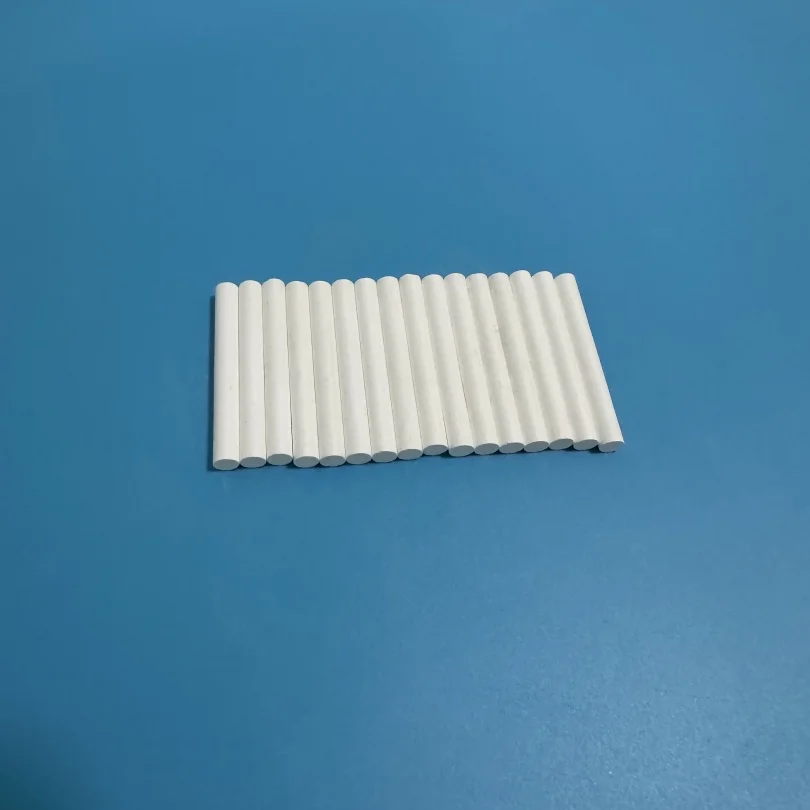

1.High thermal conductivity and excellent insulation performance

2. Strong resistance to high temperature and thermal shock

3.Suitable for semiconductor fixtures

1.The core advantage of boron nitride rods lies in their unique thermal management capabilities. It not only has excellent thermal conductivity (usually in the range of 30-60 W/m · K, and even higher for some oriented materials), but also can quickly conduct and disperse heat from the heat source area, avoiding the failure of electronic devices or high-temperature devices due to local overheating; At the same time, it is also an excellent electrical insulator that can maintain good insulation performance even at high temperatures. This rare combination of "high thermal conductivity" and "high insulation" makes it the preferred material for solving the contradiction between heat dissipation and insulation in high-power density electronic devices (such as IGBTs, lasers) and semiconductor manufacturing equipment (such as electrostatic chucks, heater bases). By using boron nitride rods as heat dissipation brackets or insulating heat transfer elements, the power density, operational stability, and service life of the equipment can be significantly improved

2.Boron nitride rods can work stably in an inert or reducing atmosphere for a long time in ultra-high temperature environments above 1800 ℃, and can also withstand sustained high temperatures of about 1200 ℃ in the atmosphere (their oxidation initiation temperature is about 850 ℃, but they can provide short-term protection after forming a dense boron oxide film on the surface). More importantly, its coefficient of thermal expansion is extremely low and isotropic, which endows it with unparalleled thermal shock resistance. Whether it is rapid cooling from a high-temperature environment or instant high-temperature heating, boron nitride rods can effectively resist the huge thermal stress caused by temperature gradients, avoiding cracking or peeling. This characteristic makes it highly reliable and durable when used as a crucible, support, or channel in processes that require frequent temperature rise and fall, such as metal melting, crystal growth, and powder sintering

3.Thanks to its hexagonal layered crystal structure similar to graphite, boron nitride rods have an extremely low coefficient of friction (usually between 0.2-0.4), making them an excellent solid lubricant material. This self-lubricating property enables it to perform well in extreme working conditions such as high temperature, high load, vacuum, or situations where liquid lubricants cannot be used (such as bearings, guide rails, and sealing rings in high-temperature kilns), effectively reducing wear and lowering operational resistance. At the same time, boron nitride has extremely strong chemical inertness and has excellent resistance to most molten metals (such as aluminum, copper, molten steel), molten salts, glass melts, as well as strong acids and bases, making it less prone to chemical reactions or corrosion. This enables boron nitride rods to maintain structural integrity and functional stability for a long time when used as components in contact with molten materials in industries such as metallurgy, chemical engineering, and glass manufacturing, such as pouring ports, thermocouple protection tubes, and stirrers.

4.Unlike many high-performance ceramics that are difficult to process, such as alumina and silicon carbide, boron nitride rods are relatively soft with a Mohs hardness of only about 2. They can be directly machined using standard hard alloy or diamond tools for precision machining such as turning, milling, drilling, planing, and grinding, without the need for expensive and time-consuming post sintering processing. This feature greatly simplifies the manufacturing process, reduces production costs and cycles, and is particularly suitable for the manufacturing of small batches, multiple varieties, and complex shaped irregular parts. Engineers can flexibly process boron nitride rods into precision parts of various sizes and shapes according to specific application requirements, such as thin-walled tubes, complex fixtures, threaded components, etc., to meet customized needs in various scenarios from semiconductor manufacturing to scientific research experiments.

5.The application range of boron nitride rods spans multiple high-tech fields. In the semiconductor industry, it is a key material for manufacturing crucibles for the growth of compound semiconductor crystals such as GaAs and GaN, as well as heating components for molecular beam epitaxy (MBE) systems. In the field of high-temperature industrial furnaces, it is used as sintering fixtures, push plates, and guide rails due to its non adhesive, high temperature resistance, and thermal shock resistance. In vacuum technology, it can serve as the insulation and support components for the hot zone of high-temperature vacuum furnaces. In the fields of aerospace and nuclear energy, it is used for structural components and neutron absorbing parts that are resistant to extreme temperatures. In addition, boron nitride rods have become an irreplaceable key material in scientific research equipment, special metallurgy, and high-performance composite material forming molds due to their comprehensive performance advantages, providing a solid material foundation for the development of modern industrial technology.

Parameter

| Property | Unit | Index |

| Thermal Conductivity (RT) | W/mK | 45-50 |

| Coefficient of Thermal Expansion (RT) | 10⁻⁶/℃ | 6.5-7.5 |

| Coefficient of Thermal Expansion (85-1000℃) | 10⁻⁶/℃ | 8.0-9.0 |

| Resistivity (RT) | Ω·m | >10¹² |

| Dielectric Breakdown Voltage | 10⁶V/m | 2.5-4.0 |

| Shore Hardness | - | 3 |

| Mohs Hardness | - | 3.8-4.3 |

| Bending Strength (RT) | MPa | >35 |

| Compressive Strength (RT) | MPa | >200 |

| Density | g/cm³ | 1.9-2.2 |

| Purity | % | 99.5 |

| Composition (Boron Content) | % | - |

| Composition (Oxygen Content) | % | <0.4 |

| Composition (Carbon Content) | % | <0.02 |

| Composition (Iron Content) | % | <0.50 |

| Working Temperature (Oxidizing Atmosphere) | ℃ | 800 |

| Working Temperature (Vacuum) | ℃ | 2000 |