Silica Quartz Glass Rod:

A quartz rod is a cylindrical solid made from fused quartz or synthetic silica. It is characterized by its exceptional properties. A fused quartz rod is a solid cylindrical bar manufactured from high-purity silicon dioxide (SiO through the fusion of natural quartz crystals or synthetic raw materials.

It is an advanced technical quartz material renowned for its exceptional combination of thermal, optical, and chemical properties, making it indispensable in high-tech industries and scientific research.

Features

- Extremely high thermal stability: It features an extremely low coefficient of thermal expansion and can withstand drastic temperature changes without cracking (thermal shock resistance). Its softening point is close to 1630°C, and the continuous service temperature can reach 1050-1100°C.

- Outstanding optical performance: It has high transmittance in the ultraviolet, visible, and infrared spectral ranges. Particularly, it exhibits excellent transmittance for short-wave ultraviolet light.

- Superior chemical purity and inertness: Composed of over 99.99% pure silicon dioxide, it has excellent resistance to most acids (except hydrofluoric acid and hot phosphoric acid). It will not contaminate sensitive environments even at high temperatures.

- High electrical insulation: It is an excellent electrical insulator and maintains stable electrical performance even at high temperatures and frequencies.

- Excellent mechanical properties: It has high rigidity and hardness, and shows good mechanical strength at room temperature. Its long-term service life is affected by the service temperature, environment, and the quality of surface treatment.

Manufacturing process

- Raw Material Preparation: Select high-purity natural quartz crystals or synthetic silicon-based materials.

- Melting: The raw materials are melted in a high-temperature electric furnace under vacuum or inert gas protection (typically above 2000°C).

- Forming: The molten quartz is drawn into uniform cylindrical rods of specific diameter and length through a precisely controlled process.

- Annealing: The formed quartz rods undergo a carefully controlled annealing process to eliminate internal stresses and ensure material stability and mechanical strength.

- Cold Working: Subsequent processing such as cutting, grinding, polishing, and fire polishing can be carried out as required to achieve precise dimensions, smooth surface finish, or specific geometries.

Main Types

- Transparent Quartz Rod: Standard type, featuring the highest optical transmission rate, suitable for optical and lighting applications.

- Opaque Quartz Rod: Contains a large number of tiny bubbles, making it opaque to visible light but usually transmits infrared rays. It often has better thermal shock resistance and is less expensive.

- Fused Quartz Rod: Made by chemical vapor deposition, it has the highest purity and superior ultraviolet transmission performance, suitable for the most demanding semiconductor and optical applications.

- Good mechanical strength. Its long-term service life is affected by the usage temperature, environment, and the quality of surface treatment.

Advantages of the quartz rod:

- High Purity: Composed primarily of silicon dioxide (SiO₂).

- High Temperature Resistance: Withstands temperatures up to 1100°C (2012°F) for short periods and can be used continuously at 1000°C (1832°F).

- Low Thermal Expansion: Highly resistant to thermal shock, meaning it doesn't crack easily when subjected to rapid temperature changes.

- Excellent Optical Transparency: Transmits a wide range of light, from the ultraviolet (UV) through the visible to the infrared (IR) spectrum.

- High Electrical Insulation: An excellent electrical insulator even at high temperatures.

- Superb Chemical Resistance: Inert to most acids and resistant to corrosion, making it suitable for harsh chemical environments.

Common Applications:

The primary applications of quartz rods, categorized by industry:

- Wafer Processing: Used as wafer boats, support rods, and paddles in diffusion furnaces and CVD (Chemical Vapor Deposition) systems to hold silicon wafers during high-temperature processing.

Optical Applications: Serve as light-guides or conduits for UV light in semiconductor manufacturing equipment.

- Lamp Envelopes / Sheaths: Used in halogen lamps, UV lamps, and high-intensity discharge lamps. The quartz protects the filament while allowing the high-temperature light emission to pass through.

Support Structures: Act as internal supports for filaments and electrodes within high-temperature lamps.

- Laboratory Apparatus: Used to make stirrers, sample holders, and thermocouple protection tubes in high-temperature furnaces and chemical experiments.

Optical Benches & Components: Utilized as sturdy, stable, and thermally invariant support structures in precision optical setups (e.g., for mounting lenses, mirrors, and lasers).

Spectroscopy: Serve as sample holders or windows in UV-Vis and IR spectrometers due to their excellent optical properties.

- Sight Glasses: Used as viewing ports in high-temperature furnaces, boilers, and reactors to allow visual monitoring of internal processes.

Thermocouple Protection Tubes: Shield thermocouples from corrosive and high-temperature environments, ensuring accurate temperature measurement.

Heat Treatment: Used as jigs, fixtures, and rollers in conveyor belts for glass and metal heat treatment processes.

- Preform Handling: Used as handling rods and support structures during the manufacturing of optical fiber preforms.

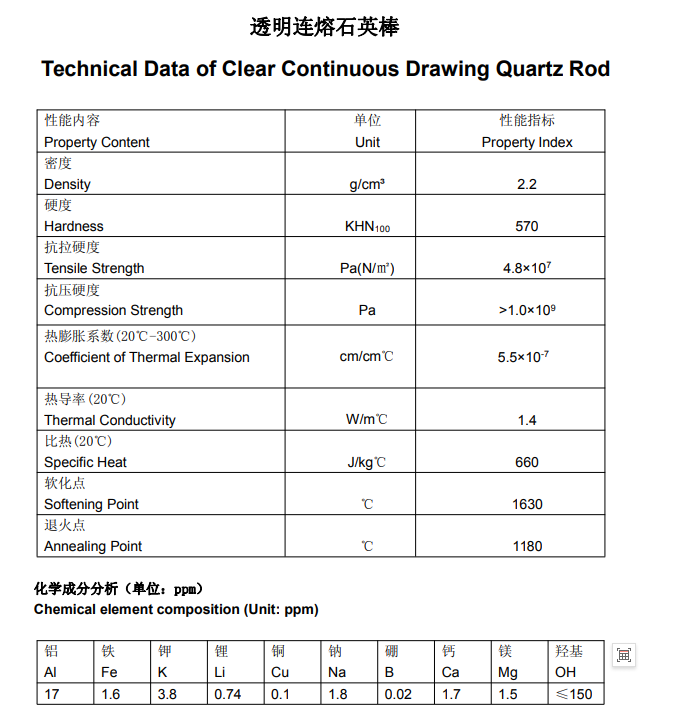

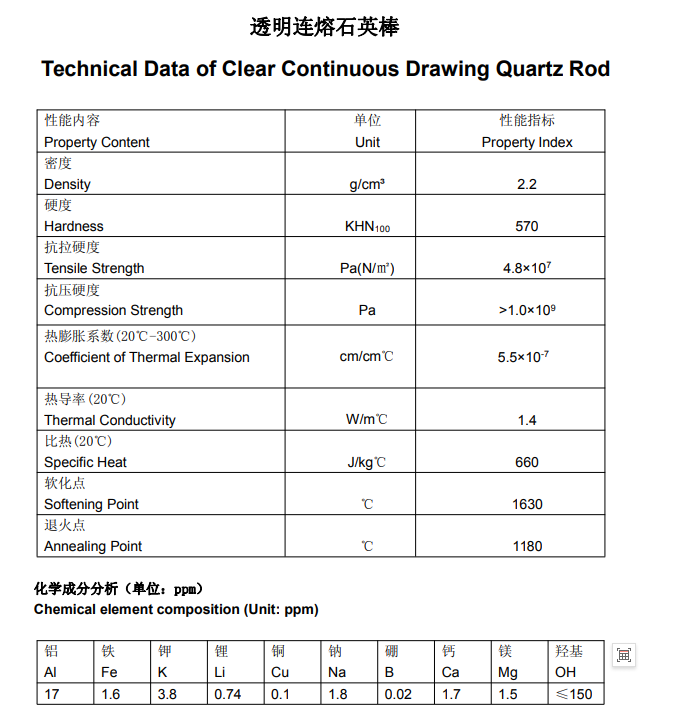

Technical specifications