9F,Bldg.A Dongshengmingdu Plaza,No.21 Chaoyang East Road,Lianyungang Jiangsu,China +86-13951255589 [email protected]

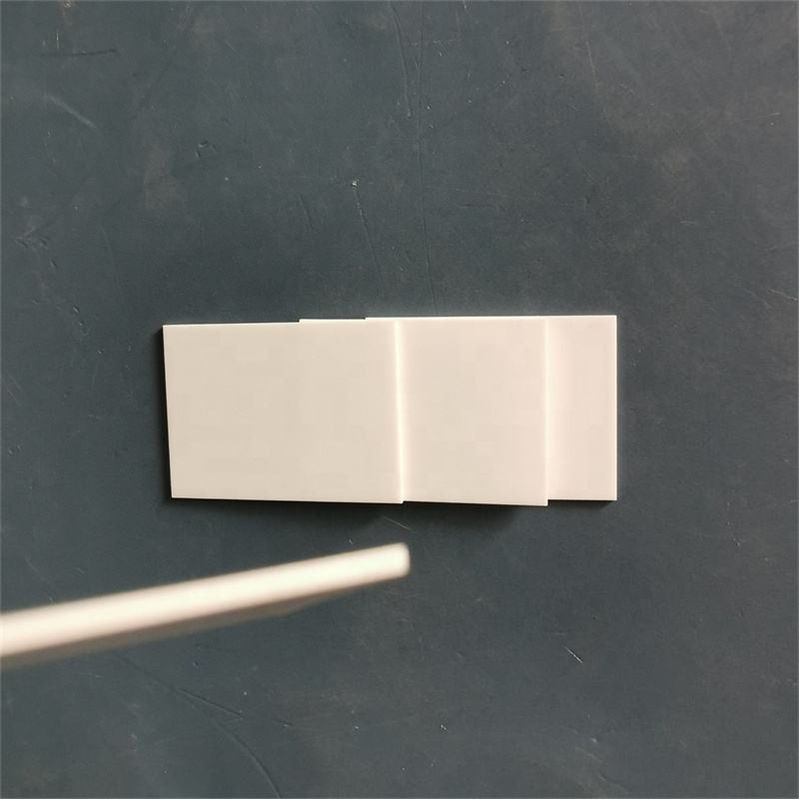

Excellent Electromechanical characteristics, thermal characteristics BeO ceramic substrate with High thermal conductivity. Request a quotation from Highborn at once.

The development of beryllium oxide ceramics plate abroad began in the 1930s, but its rapid development phase was from the late 1950s to the late 1970s. Beryllium oxide ceramics are different from other electronic ceramics. To date, their high thermal conductivity and low-loss characteristics are difficult to replace with other materials.

On one hand, this is due to the significant demand in various fields of science and technology, and on the other hand, because beryllium oxide is toxic, requiring strict and challenging protective measures, there are very few factories in the world capable of producing it safely.

Beryllium oxide ceramics substrate are ceramics with beryllium oxide as the main component. They are mainly used as substrates for large-scale integrated circuits, high-power gas laser tubes, heat sink housings for transistors, microwave output windows, and neutron moderators.

It is made by adding ingredients such as aluminum oxide to beryllium oxide powder and sintering at high temperatures. Manufacturing this type of ceramic requires proper protective measures. In high-temperature media containing moisture, the volatility of beryllium oxide increases, beginning to volatilize at 1000°C and increasing with temperature, which creates production difficulties, and some countries no longer produce it. However, the products have excellent properties, and despite their high price, there is still considerable demand.

The use of BeO sheet as an insulating material began in 1928, but until 1930, BeO was mainly mixed with other materials as a phosphorescent substance.

During World War II, high-purity beryllia ceramics plate were first manufactured. In 1946, it was discovered that beryllium oxide has an extremely high thermal conductivity. At that time, it was mainly used in nuclear devices. It was not until the mid-1950s that beryllium oxide started to be applied in electronics, measuring instruments, communications, and aerospace technology.

The melting temperature range of beryllium oxide substrate is 2530°C to 2570°C, with a theoretical density of 3.02 g/cm³. It can be used long-term at 1800°C in a vacuum, at 2000°C in inert gases, and begins to volatilize at 1800°C in an oxidizing atmosphere. The most remarkable property of beryllium oxide ceramics is its high thermal conductivity, comparable to metallic aluminum, and 6-10 times that of aluminum oxide. It is a dielectric material with unique electrical, thermal, and mechanical properties, and no other material exhibits such a comprehensive range of properties.

Beryllium oxide ceramics sheet are valued and applied in the fields of microwave technology, vacuum electronics, nuclear technology, microelectronics, and optoelectronics due to their high thermal conductivity, high melting point, strength, high insulation, low dielectric constant, low dielectric loss, and good adaptability to packaging processes. Particularly, they have been the mainstream ceramic materials for manufacturing high-thermal-conductivity components in high-power semiconductor devices, high-power integrated circuits, high-power microwave vacuum devices, and nuclear reactors, playing a very important role in both the military field and the national economy.

In aerospace electronic technology conversion circuits, as well as in aircraft and satellite communication systems, BeO plate is extensively used for bracket and assembly components; it also has potential applications in spacecraft electronics. BeO ceramics possess exceptionally high thermal shock resistance and can be used in jet aircraft detonators. BeO plates with metal coatings have been used in the control systems of aircraft propulsion devices, and sprayed metal beryllium oxide liners have been applied in automobile ignition devices.

BeO ceramics plate have excellent thermal conductivity and are easy to miniaturize, showing broad application prospects in the laser field; for instance, BeO lasers are more efficient and have higher output power than quartz lasers. The use of BeO ceramic materials in aerospace, space, and military equipment plays an irreplaceable role, and therefore, the demand for BeO has been increasing year by year.

In the United States, the production of BeO sheet in the late 1990s was 3 to 5 times that of the late 1980s, and it is currently increasing at a rate of 8–12%, reaching more than 200 tons. Several years ago, the U.S. Defense Electronics Supply Center proposed a plan to the industry to develop high-performance BeO ceramic materials and has since made progress. In the supply center's materials catalog, the status of beryllium oxide sheet is gradually rising, and in the coming years, beryllium oxide will be the preferred material for military high-power MCMs (multi-chip modules).

Technical Specifications

Name |

Beryllium oxide |

||

Volume density |

|

||

Purity |

99.90% |

||

Flexural strength |

140MPa |

||

Thermal conductivity |

250 W/m.k |

||

Dielectric constant |

1 MHz 20℃ 6.5~7.510 GHz 20℃ 6.5~7.5 |

||

Dielectric loss tangent |

1 MHz 20℃ ×10-4 ≤4 |

||

Volume resistivity |

100 ℃ ≥ 1013 Ω.m |

||

Impact strength |

KV/mm ≥ 15 |

||

Chemical stability |

1.9 HCl ug/cm3 ≤0.3 |

||