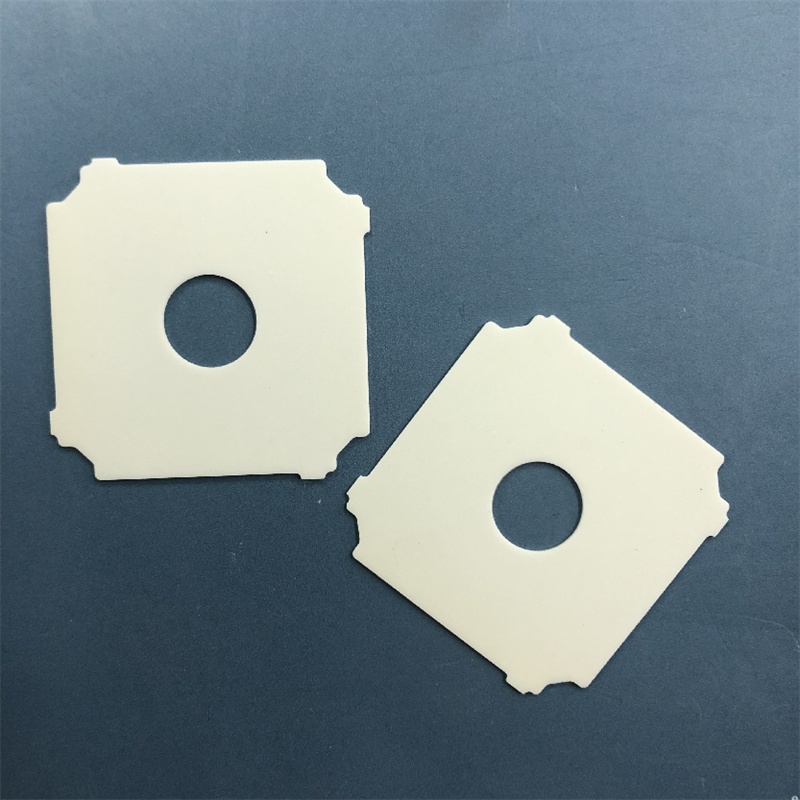

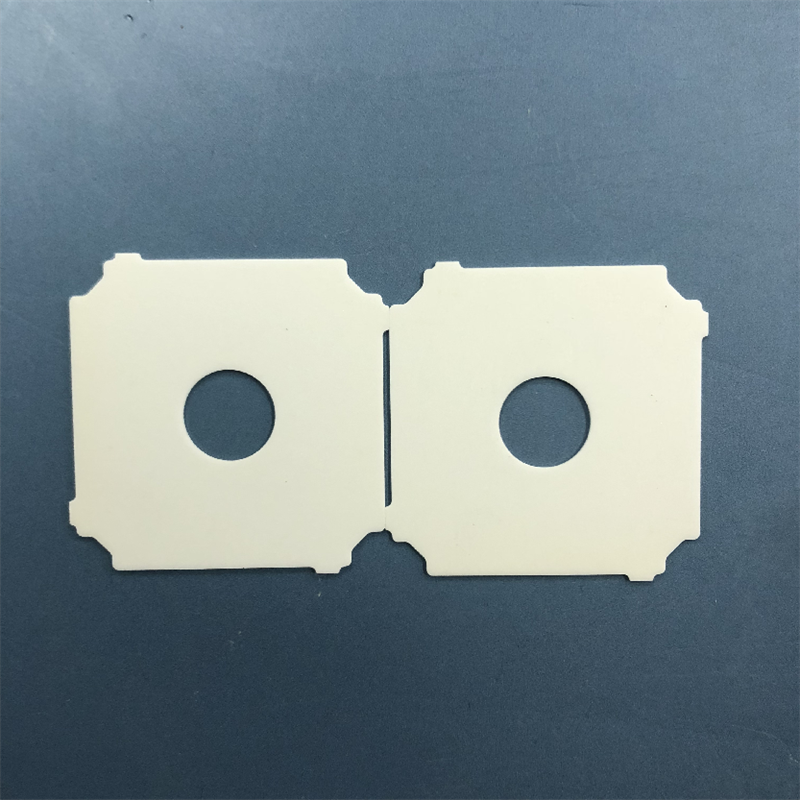

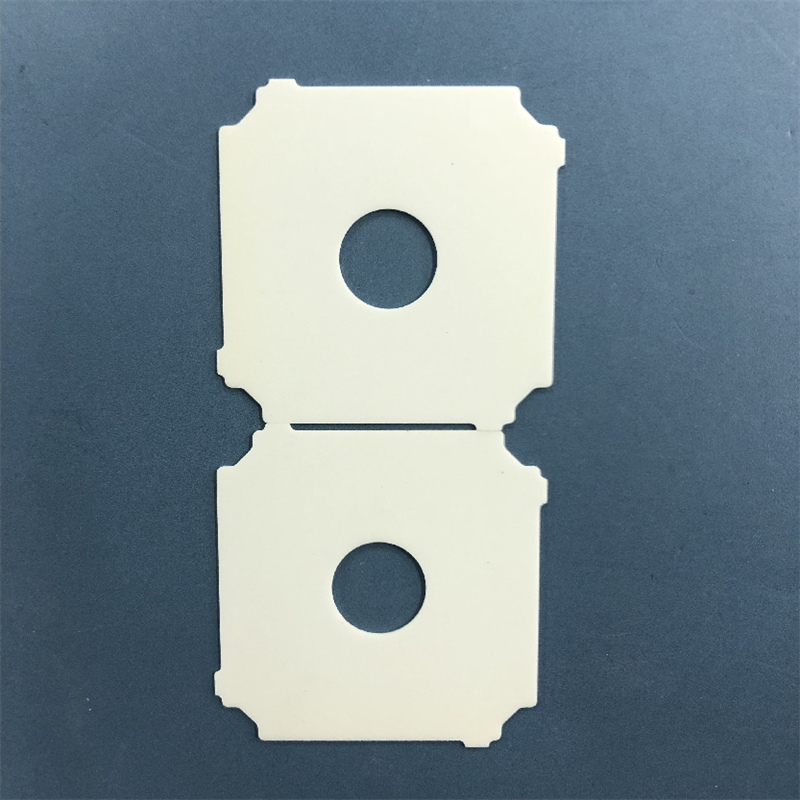

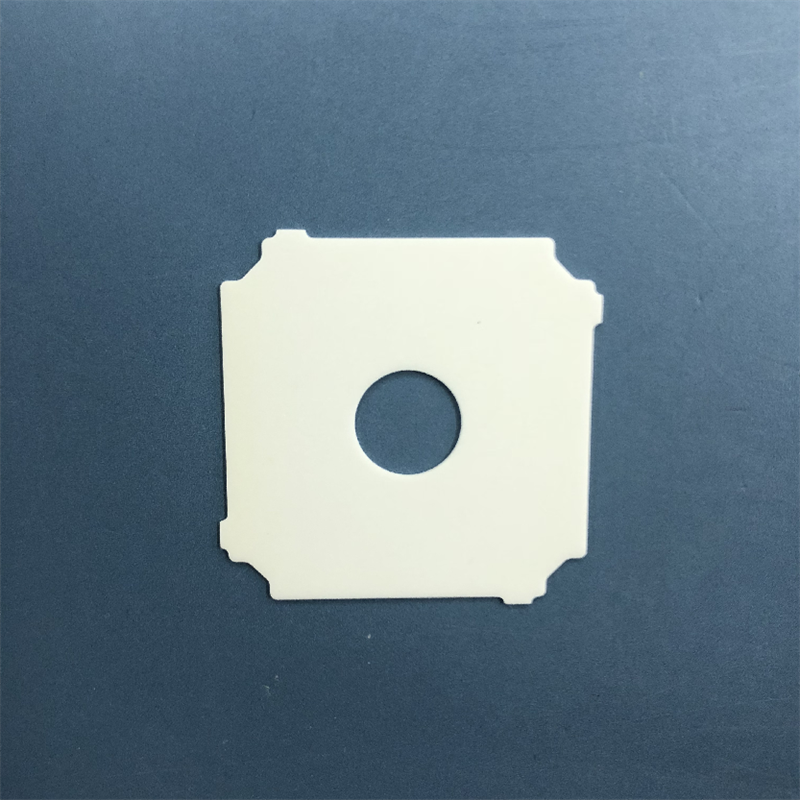

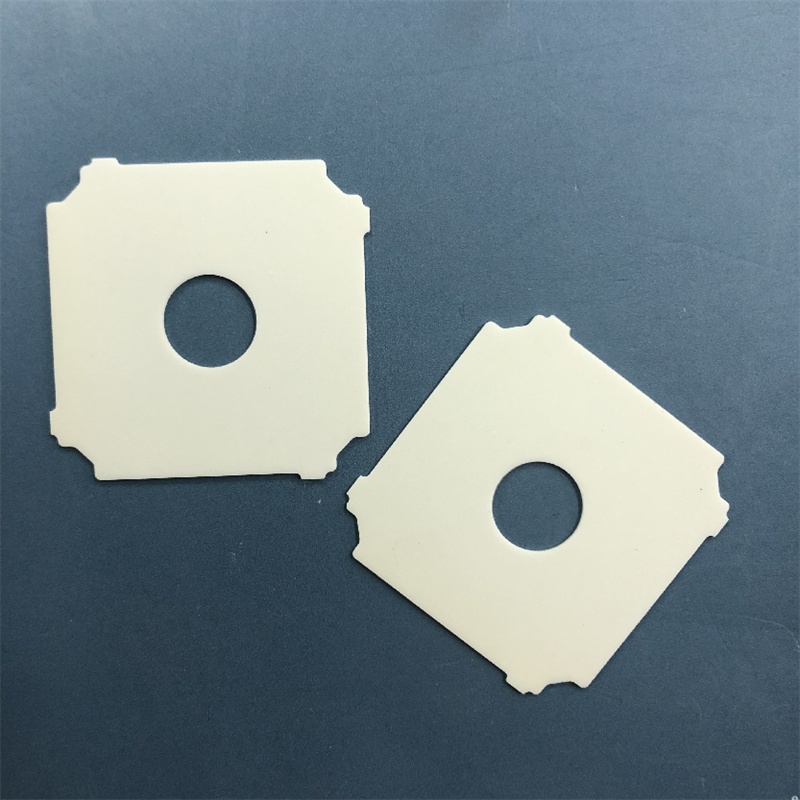

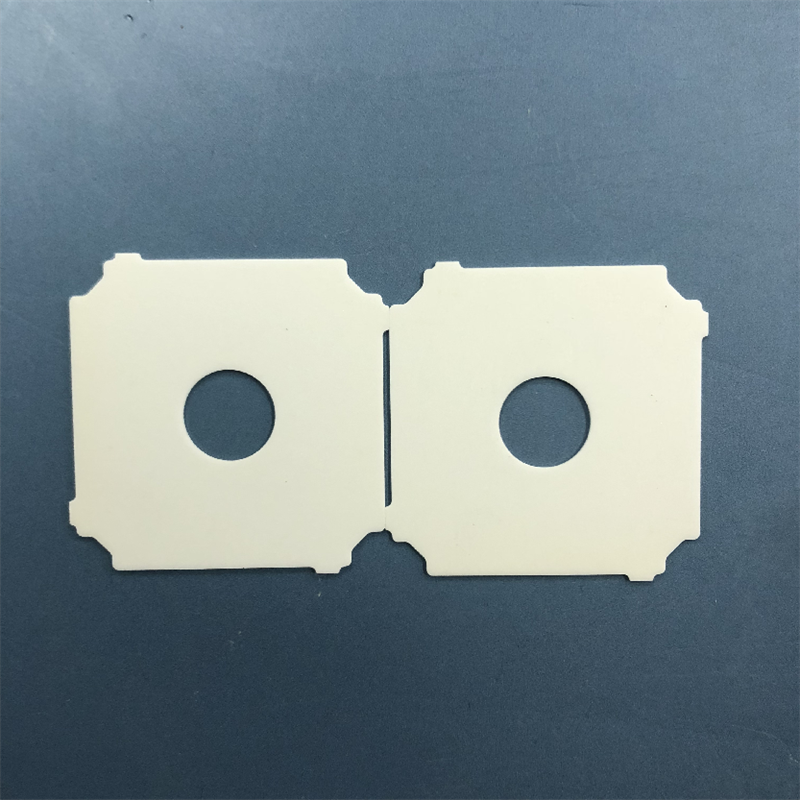

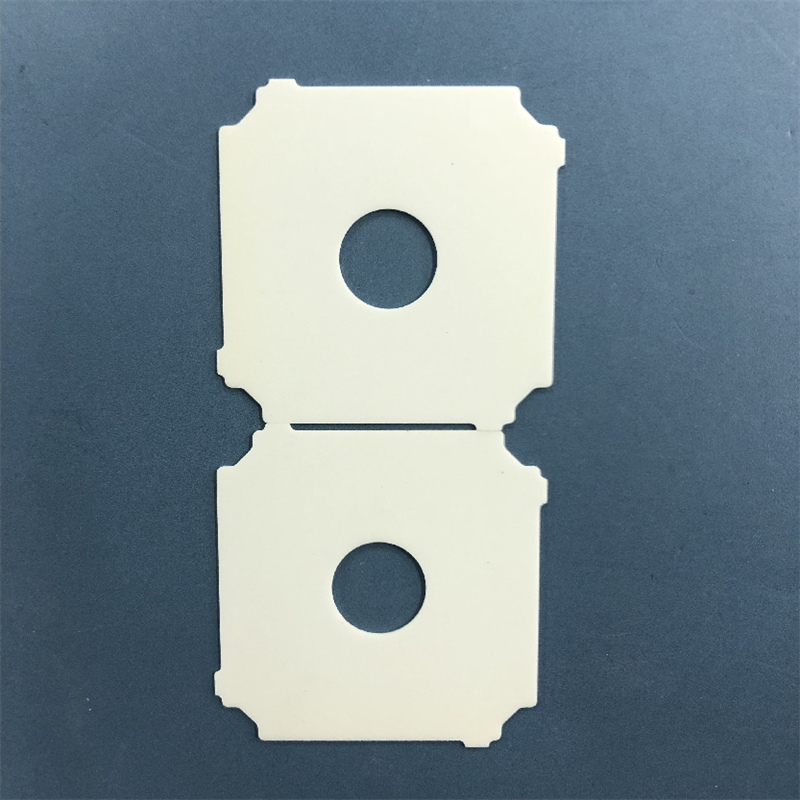

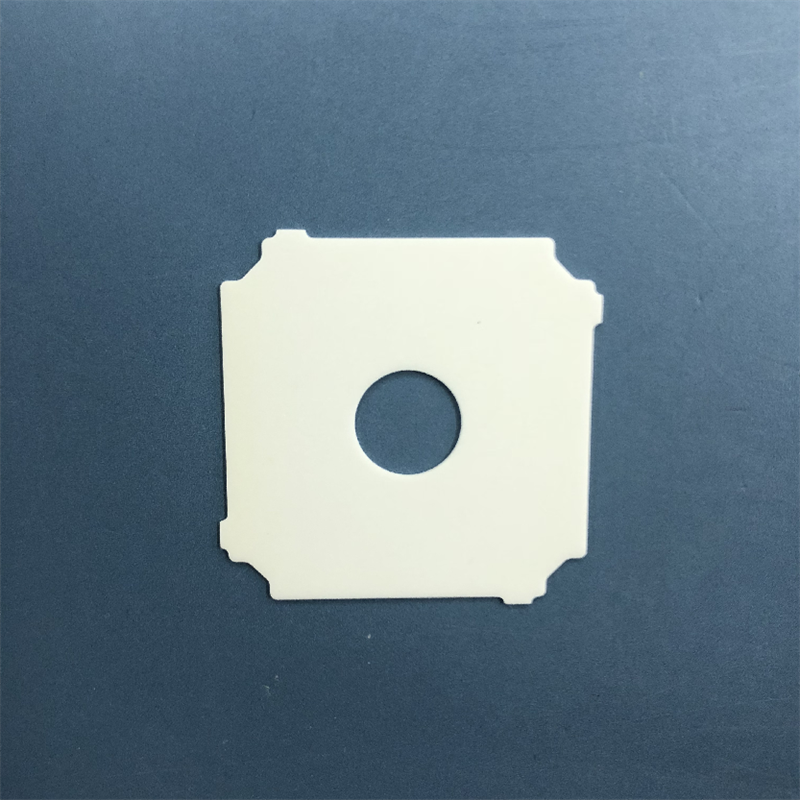

Product Overview

The 96% alumina ceramic substrate is manufactured using advanced ceramic processes, offering excellent thermal conductivity, electrical insulation, and mechanical strength. This product is widely used in demanding fields such as power semiconductors, new energy vehicles, and industrial control, providing reliable packaging solutions for various electronic components. We offer standard-sized inventory while supporting comprehensive customization services to meet the personalized needs of different customers.The primary manufacturing techniques are tape casting and gel casting.

-

Tape Casting Technology:This method is widely used for producing thin ceramic sheets, with particular emphasis on slurry preparation and sintering.

- Sintering and Densification: The dried green tape is sintered at high temperatures.

-

Gel Casting Technology:This technique is more suitable for producing ultra-thin ceramic substrates, utilizing in-situ chemical solidification of the slurry.

Advantages of al2o3 ceramic substrate

Excellent Thermal Management Performance

- - Thermal conductivity reaches 24 W/m·K, over 5 times that of traditional FR-4 substrates.

- - Effectively reduces the operating temperature of power devices, extending product service life.

- - Ensures stable operation of high-power devices in high-temperature environments.

Superior Electrical Insulation Properties

- - Insulation strength >14 kV/mm, meeting high-voltage application requirements.

- - Stable dielectric constant of 9.6@1MHz, ensuring signal transmission integrity.

- - Volume resistivity >10¹⁴ Ω·cm, providing reliable electrical isolation.

Strong Mechanical Performance

- - Flexural strength >300 MPa, withstands harsh mechanical stress.

- - Coefficient of thermal expansion 6.8×10⁻⁶/°C, well-matched with chip materials.

- - Hardness >80 HRA, offering good wear and corrosion resistance.

Standard Inventory Specifications

Regular Dimensions

- - Square substrates: 50×50mm to 150×150mm.

- - Circular substrates: Φ30mm to Φ200mm.

- - Special shapes: Support for standard package sizes like TO-220, TO-247, TO-3P.

Thickness Series

- - Ultra-thin series: 0.25mm, 0.38mm, 0.5mm.

- - Standard series: 0.635mm, 0.8mm, 1.0mm.

- - Thick plate series: 1.5mm, 2.0mm.

Surface Treatments

- - Standard surface: Surface roughness Ra ≤ 0.4um.

- - Fine polishing: Surface roughness Ra ≤ 0.1um.

- - Metallization options: Copper plating, silver plating, gold plating, etc.

Customization Services

We provide comprehensive customization services:

- - Dimension Customization: Support for non-standard sizes and special shapes.

- - Hole Design: Capable of processing various through-holes, blind holes, and special-shaped holes.

- - Metallization Customization: Thick film printing, DBC copper cladding, thin film metallization.

- - Special Treatments: Laser cutting, chamfering, surface roughening.

Application Cases of 96% al2o3 ceramic chip

Case One: New Energy Vehicle Motor Drive

Customer: A well-known automotive electronics supplier.

Challenge: IGBT modules had insufficient heat dissipation in high-temperature environments, leading to reduced system reliability.

Solution:

- - Used 0.635mm thick 96% alumina ceramic substrate.

- - Applied DBC copper cladding surface treatment with 0.3mm copper layer thickness.

- - Designed multi-hole structure to optimize heat dissipation paths.

Results:

- - Module operating temperature reduced by 35°C.

- - System reliability improved to 99.5%.

- - Product lifespan extended to 100,000 hours.

Case Two: Industrial-Grade Servo Drive

Customer: A leading industrial automation company.

Requirement: Power modules required both heat dissipation performance and insulation strength.

Solution:

- - Selected 1.0mm thick 96% alumina substrate.

- - Used thick film metallization process with silver-palladium electrode printing.

- - Achieved multi-layer circuit structure, reducing module size.

Results:

- - Withstand voltage reached AC2500V.

- - Power density increased by 40%.

- - Achieved UL certification, meeting Industrial Grade 4 standards.

Case Three: Photovoltaic Inverter Power Module

Customer: A new energy equipment manufacturer.

Challenge: Large outdoor temperature variations required excellent temperature cycling performance.

Solution:

- - Used 0.8mm polished-grade substrate.

- - Applied special edge treatment process.

- - Optimized metal layer pattern design.

Results:

- - Passed 1000 cycles of -40℃to 125℃ temperature cycling test.

- - Failure rate reduced to below 0.1%.

- - Successfully applied in megawatt-level photovoltaic power stations.

Quality Assurance System

We strictly implement the ISO9001 quality management system to ensure product quality:

- - Raw material inspection: Full-index testing of alumina powder.

- - Process control: Implementation of SPC statistical process control.

- - Finished product inspection: 100% testing of dimensions, appearance, and performance.

- - Reliability testing: Regular lifespan and environmental adaptability tests.

Service Commitment

- - Fast Delivery: Standard specifications shipped within 3-5 days.

- - Technical Support: Professional application solution design.

- - Sample Service: Free samples provided for testing.

- - After-Sales Guarantee: Unconditional return or exchange within 30 days for quality issues.

With its exceptional comprehensive performance, the 96% alumina ceramic sheet has become the preferred base material for high-reliability electronic equipment. Leveraging mature production processes and a complete quality management system, we provide customers with full-range services from standard products to customized solutions. Whether for bulk purchases or special requirements, we offer the most professional technical support and the highest quality products and services.

Product Parameter Table

| Material |

Al2O3 |

| 96% |

99.60% |

| Color |

White |

White |

| Density (g/cm³) |

3.75 |

3.9 |

| Porosity (%) |

0 |

0 |

| Thermal conductivity (W/m.K) 20 - 100℃ |

24 |

28 |

| Thermal Expansion (10⁻⁶ / K) 20 - 1000℃ |

8 |

8.5 |

| Dielectric Constant (at 1MHz) |

9.8±10% |

10.1±10% |

| Loss Tangent (10⁻⁴ @1MHz) |

3 |

2 |

| Volume Resistivity (ohm.cm) 200℃ |

≥10¹² |

≥10¹³ |

| Modulus of elasticity (GPa) |

340 |

350 |