Performance and Characteristics

The performance of silicone rubber protective shell lies in its special molecular structure with a main chain of silicon oxygen bonds (Si-O), which makes it fundamentally different from organic polymer materials such as TPU and PC.

- Excellent elasticity and cushioning:

- High resilience: maintains excellent softness and elasticity over a wide temperature range, effectively absorbs and disperses impact energy, and provides excellent drop and vibration protection.

- Soft Touch: Provides a skin friendly and delicate "skin like" feel, providing a great user experience.

- Extreme temperature adaptability:

- High and low temperature resistance: The working temperature range is extremely wide, usually from -50 ℃ to+200 ℃, and can withstand higher/lower temperatures in the short term. It does not harden or become brittle in severe cold environments, and does not undergo sticky deformation at high temperatures, with stable performance.

- Excellent chemical and environmental stability:

- Weather resistance: resistant to ultraviolet rays, ozone, and radiation, and not easily aged, yellowed, or cracked after long-term outdoor use.

- Corrosion resistance: It has good resistance to weak acids, weak bases, salt solutions, alcohol, etc., and is easy to clean with disinfectants such as alcohol.

- Inert and Safe: Non toxic and odorless, meets food grade and medical grade standards, has good biocompatibility, and does not cause skin allergies.

- Electrical insulation and flame retardancy:

- Excellent insulation: It can maintain good insulation performance even in humid and high temperature environments.

- High flame retardant rating: can pass flame retardant certifications such as UL94 V-0, meeting strict fire protection requirements.

- Physical characteristics:

- Breathability: It has moderate breathability.

- Easy to clean: The surface is hydrophobic, not easily contaminated with dust, and stains are easy to wipe.

- Color stability: The color masterbatch is evenly dispersed and the color is long-lasting.

Main drawbacks:

- Moderate wear resistance: Long term friction may cause the surface to shine or wear.

- Tear strength: Compared to some engineering plastics, it is lower.

- High price: The raw material and production costs are higher than TPU, PC, etc.

- The phenomenon of "sticky dust": static electricity may adsorb fine dust.

Production process

High end silicone protective cases mainly use liquid silicone injection molding technology, which is an efficient, precise, and automated production method.

- Raw material preparation:

- Use two-component liquid silicone rubber, with component A (containing platinum catalyst) and component B (containing hydrogen silicone oil crosslinking agent) stored separately. Color paste can be added for color matching.

- Measurement mixing: A and B components are accurately transported to a dynamic mixer in a 1:1 ratio through a precision metering pump, and mixed evenly in an instant.

- Injection molding: The mixed liquid rubber material is injected into the preheated mold cavity under lower pressure.

- Heat curing: The mold temperature is usually between 150-200 ℃. Silicone undergoes an addition reaction (catalyzed by platinum) inside the mold cavity, with no by-products released, and rapidly solidifies into shape (usually in a few tens of seconds).

- Mold extraction: After curing is completed, the automated robotic arm extracts the product with almost no burrs.

- Remove the sprue: Trim the sprue marks (usually very small).

- Secondary curing: Some products with extremely high requirements will be briefly baked to thoroughly complete the reaction and improve performance.

- Surface treatment: can be sprayed (feel oil, anti fouling coating), printed (logo, pattern), laser engraving, etc.

- Cleaning and inspection: After cleaning, conduct a full inspection of size, appearance, and function.

- Process advantages: short molding cycle, high degree of automation, less waste, high product size accuracy, clean and environmentally friendly (solvent-free).

Processing method

The processing of silicone rubber protective shells mainly occurs in the molding stage and post-processing stage:

Mold processing: The mold is the core of LSR technology and requires the use of high-quality mold steel. The surface of the mold cavity is highly polished or treated with special coatings (such as nickel PTFE) to ensure smooth demolding and a smooth surface finish of the product.

Forming processing: Achieving large-scale and efficient production through multi cavity molds and automated assembly lines.

Secondary processing:

Surface spraying: Spray PU or silicone hand feel oil to enhance the tactile sensation and reduce the phenomenon of "sticking ash".

Printing: Screen printing, transfer printing of patterns or text.

Laser engraving/marking: permanent marking of serial numbers, logos, or personalized patterns.

Assembly: Assemble with metal inserts, buttons, and other plastic parts.

Core advantages of the product (compared to TPU/PC shell)

Characteristic dimension: Silicone rubber protective shell, ordinary TPU/PC shell.

Excellent hand feel and elasticity, soft and highly elastic, with a skin friendly touch ranging from good to average, and a wide range of hardness.

Extremely wide temperature range (-50 ℃~200+℃) and narrow (easily deformed around -20 ℃~80 ℃).

Excellent aging resistance, UV and ozone resistance, no yellowing or brittleness after long-term use, but prone to yellowing and aging.

Excellent chemical stability, moderate resistance to disinfectants and sweat corrosion, some chemicals may cause corrosion.

High safety and environmental protection, food grade, non-toxic and odorless, mainly industrial grade.

Excellent electrical performance and flame retardancy, high insulation, easy to reach high flame retardant level, moderate, requiring special modification.

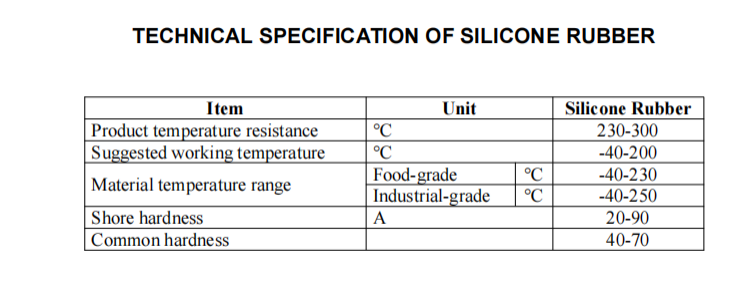

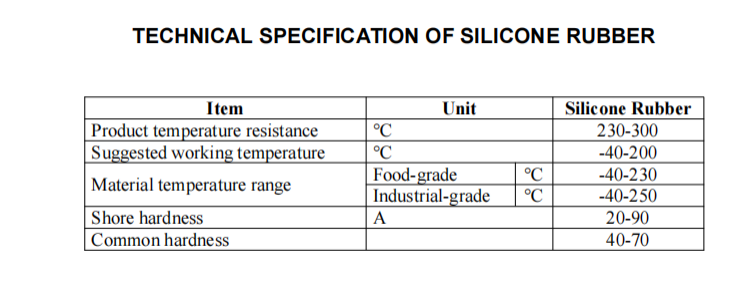

Technical specification