9F,Bldg.A Dongshengmingdu Plaza,No.21 Chaoyang East Road,Lianyungang Jiangsu,China +86-13951255589 [email protected]

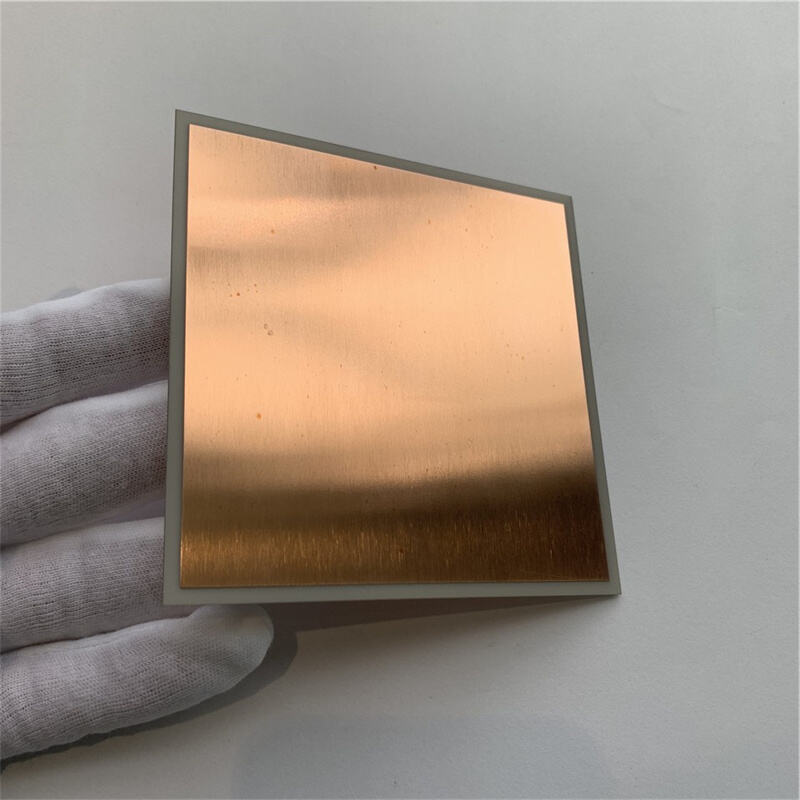

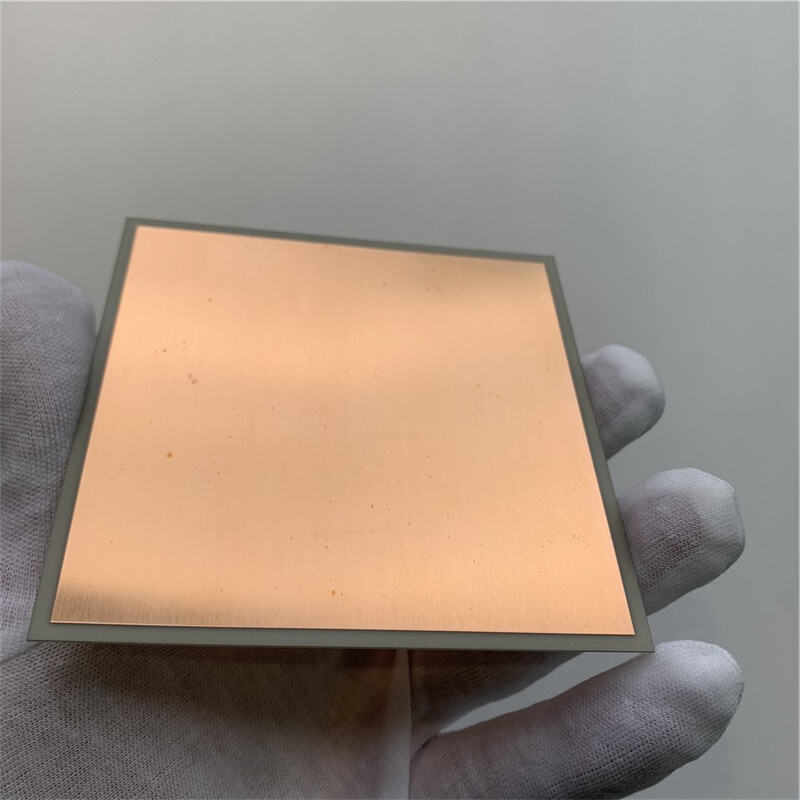

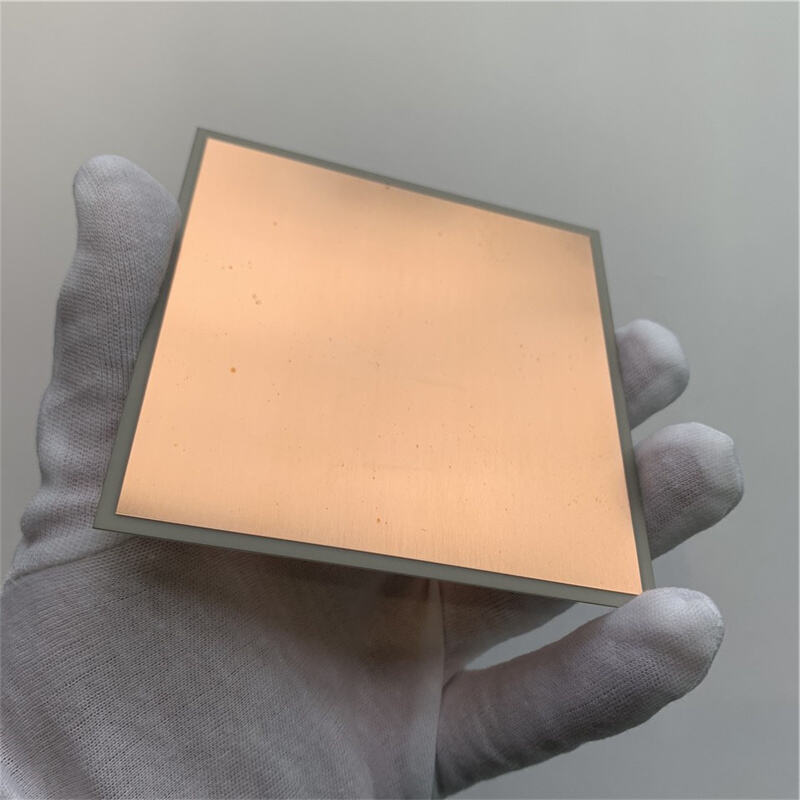

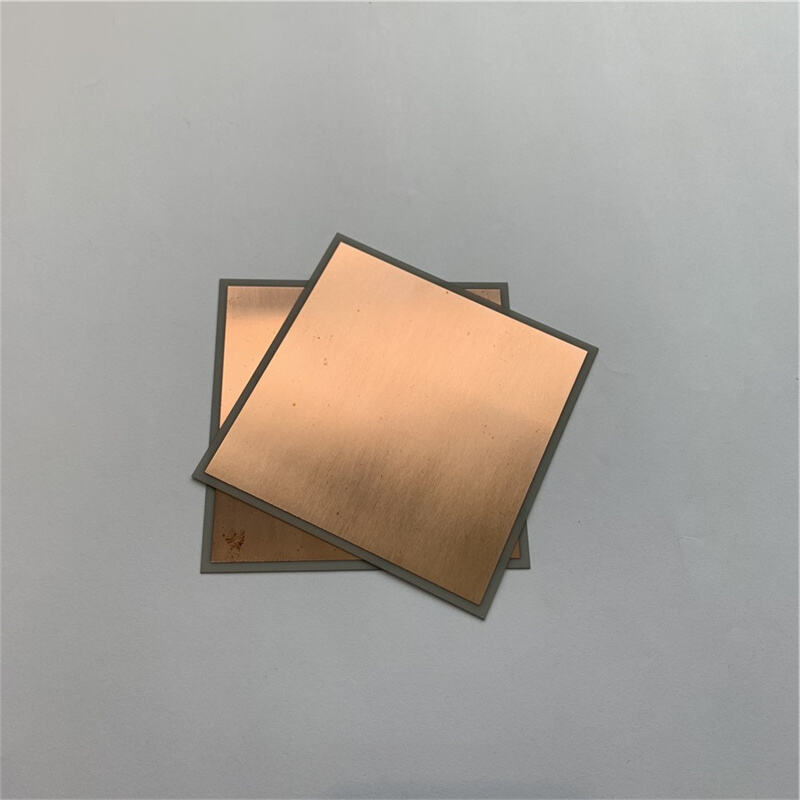

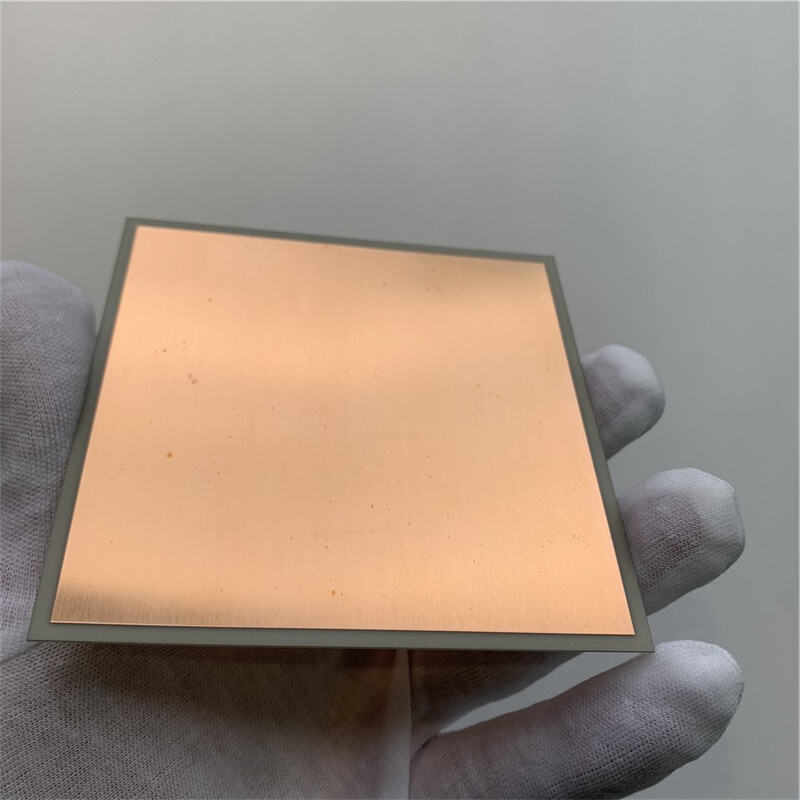

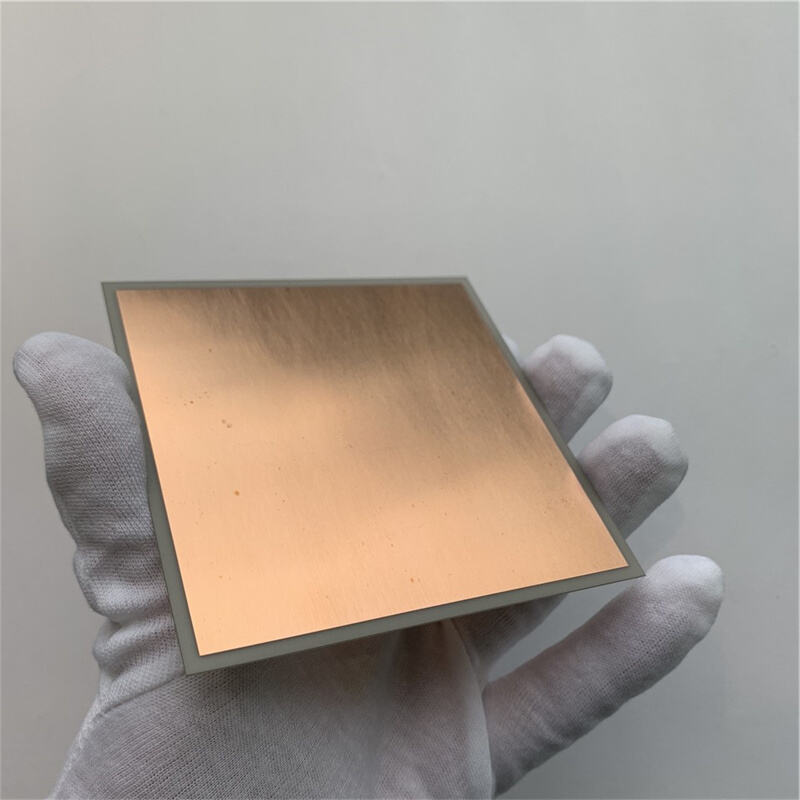

Ceramic based copper-clad laminate is a composite substrate manufacturing process that bonds copper foil to aluminum oxide or aluminum nitride ceramic substrates at high temperatures. This material has high thermal conductivity, excellent electrical insulation, and strong adhesion strength. It supports pattern etching and has high current carrying capacity. It is widely used in high-power power semiconductor modules, new energy vehicles, IGBT power modules, and other fields.

Brief

Ceramic based copper-clad laminate is a composite substrate manufacturing process that bonds copper foil to aluminum oxide or aluminum nitride ceramic substrates at high temperatures. This material has high thermal conductivity, excellent electrical insulation, and strong adhesion strength. It supports pattern etching and has high current carrying capacity. It is widely used in high-power power semiconductor modules, new energy vehicles, IGBT power modules, and other fields.

Details

Characteristic:

High strength, high thermal conductivity, and high insulation;

Strong mechanical stress, stable shape, can be connected with mosquito nails;

Strong adhesion and corrosion resistance;

Excellent thermal cycling performance, with up to 50000 cycles and high reliability;

Structures that can be etched into various patterns, similar to PCB boards (or IMS substrates);

The operating temperature range is -55 ℃ to 850 ℃;

The thermal expansion coefficient is close to that of silicon, simplifying the production process of power modules.

Application:

Widely used in high-power power semiconductor modules; Semiconductor cooler, electronic heater; Power control circuit, power hybrid circuit; Intelligent power components; High frequency switching power supply, solid-state relay; Automotive electronics, aerospace and military electronic components; Solar panel components; Telecommunications dedicated switch, receiving system; Industrial electronics such as lasers.

Parameter

| Copper coated ceramic board | |

| Plate thickness specification (mm) | 0.127mm~ 3.0mm |

| Number of layers | 2 |

| Thickness of copper foil substrate (um) |

1UM~ 1000UM (0.0285 ounce ~28.5 ounce) |

| Minimum line width/line spacing (mm) | 0.05mm |

| Minimum borehole diameter (mm) | 0.06mm(Conductive hole) |

| Finished aperture tolerance (mm) | 0.05mm (plug-in hole) |

| External tolerance (mm) | 0.05mm |

|

Minimum distance from circuit to board edge (mm) |

0.1mm |

| Hole tolerance (mm) | ± 0.05mm |

|

Finished product thickness tolerance (mm) |

(0.25-0.38mm) ± 0.03mm |

| (0.38-0.635mm) ± 0.04mm | |

| (0.76-2.00mm) ± 0.05mm | |

| Surface Treatment |

Sinking nickel gold/Sinking nickel palladium gold/Sinking silver |