9F,Bldg.A Dongshengmingdu Plaza,No.21 Chaoyang East Road,Lianyungang Jiangsu,China +86-13951255589 [email protected]

high grinding efficiency Alumina Ceramic grinder core with Aluminum Rod. Request a quotation from Highborn at once.

Most grinders on the market also use high-hardness ceramic materials – a good core makes for good grinding. This type of grinder can grind not only pepper but also coffee, Sichuan pepper, prickly ash, cumin, sea salt, legumes, and other small-particle seasonings.

Currently, existing coffee machine ceramic grinder cores are usually made of alumina. Grinding does not generate heat, which better preserves the original flavor. The coarseness of the grind can be adjusted with a nut: clockwise for finer, counterclockwise for coarser.

Advantage

Ceramic grinder cores allow for easy grinding, long-lasting use, removal of fishy or greasy tastes, rich flavor, fine powder texture, compact and attractive design, strict craftsmanship, and convenient use.

Alumina ceramic grinder cores paired with sturdy aluminum rods offer good wear resistance, high hardness, tight fastening and compression resistance, are not easy to rust, and combine both aesthetics and practicality in the overall structure, giving the product outstanding performance. The use of more scientific production and manufacturing methods brings you a brand-new experience.

A pepper grinder is made up of multiple components, mainly divided into the grinding core and the outer casing, which are made of different materials.

Common materials for the grinding core:

Common materials for the grinding core include ceramic and stainless steel, each with its own advantages and disadvantages:

The advantage of a ceramic grinding core is the lower cost, and it can be used to grind pepper and sea salt, but its grinding efficiency is not as high as stainless steel;

A stainless steel grinding core has high grinding efficiency and requires less effort, but salt can easily corrode the metal, and some types of sea salt tend to absorb moisture from the surrounding environment, becoming damp and making the metal more prone to rust. Therefore, a stainless steel grinding core is not suitable for grinding sea salt.

The material of the blade disc is not the main factor determining sharpness. Design and manufacturing process are what determine sharpness. In fact, the sharpest knives in the world are still stainless steel knives. This is because ceramic blade discs are almost always molded as a single piece, and their workability after molding is very limited.

A blade disc will not generate heat without friction from collisions. The temperature of ground coffee rises due to the pressure exerted on the coffee beans by the blade disc during grinding, as well as the friction between the beans and the disc.

The heat is generated by the coffee beans themselves being crushed and ground, regardless of the speed; to achieve the intended grind size, the necessary effort must be applied. A slower rotation simply extends the time over which heat is produced. While slower rotation increases the time the grounds stay on the blade disc and thus reduces heat, when combined with the extended time factor (time extended, heat reduced)

Common materials for shells:

The shells can be made of plastic, glass, stainless steel, or wood. The choice mainly affects the appearance and has little impact on actual grinding performance.

Wooden shells, commonly made from beech, oak, or ebony, have a textured feel and look high-end; stainless steel shells are wear-resistant and durable; plastic shells, often made from acrylic or ABS, are lightweight; glass shells are transparent and beautiful.

Most affordable universal grinders on the market feature ceramic grinding cores, which are fired under high temperature and pressure. They are aesthetically pleasing, practical, highly durable, and provide a finer, smoother grind. Ceramic cores grind quickly, wear slowly, are hard, easy to operate, and allow easy rotation to grind coarse or fine seasonings. Grinding your own spices enhances flavor. Ceramic cores are easy to disassemble, fully washable, safe to use, odor-free, durable, high in hardness, convenient, and versatile. These generally can grind pepper and sea salt. The shell materials vary and mainly depend on personal preference.

Material characteristics

Pepper grinder materials can be categorized by grinding core material into plastic, ceramic, and stainless steel/carbon steel.

Plastic: Most disposable bottles sold in supermarkets are plastic (low cost, inexpensive, can produce residue when worn, not durable, and poor quality may be harmful).

Alumina Ceramic: Good-quality ceramic materials have wear resistance second only to diamond, are non-metallic and non-porous, effectively resisting bacterial growth; their thermal conductivity is much lower than steel, ensuring minimal heat and better aroma retention; they are white and smooth with a jade-like elegance. Additionally, they are non-toxic, pollutant-free, non-oxidizing, free of heavy metals, corrosion-resistant, wear-resistant, eco-friendly, and washable. Ceramic can be used for grinding salt, Sichuan pepper, and other seasonings.

Stainless steel (carbon steel): High hardness, wear-resistant, corrosion-resistant, and long-lasting. Although stainless steel/carbon steel is more durable than ceramic, it is also more expensive and not suitable for grinding coarse salt because it can damage the carbon steel grinder and cause corrosion; low-quality stainless steel/carbon steel with low purity can rust easily.

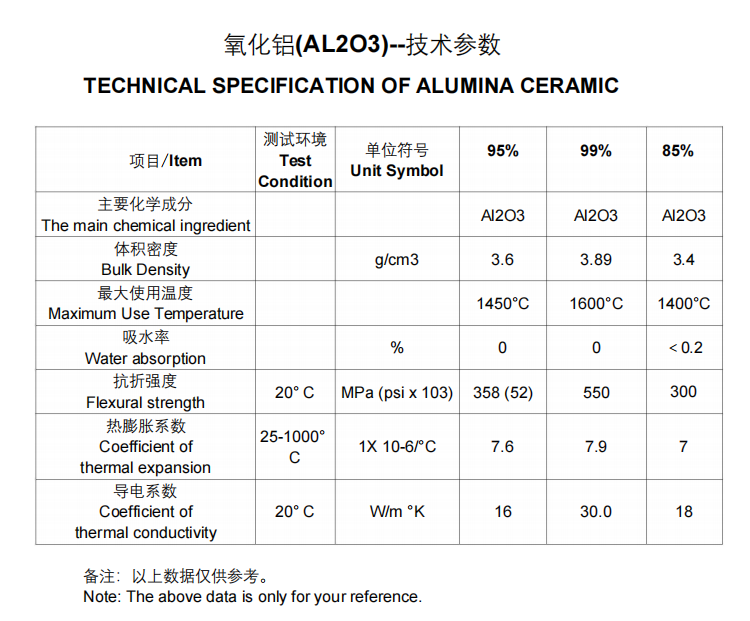

Technical specifications