9F,Bldg.A Dongshengmingdu Plaza,No.21 Chaoyang East Road,Lianyungang Jiangsu,China +86-13951255589 [email protected]

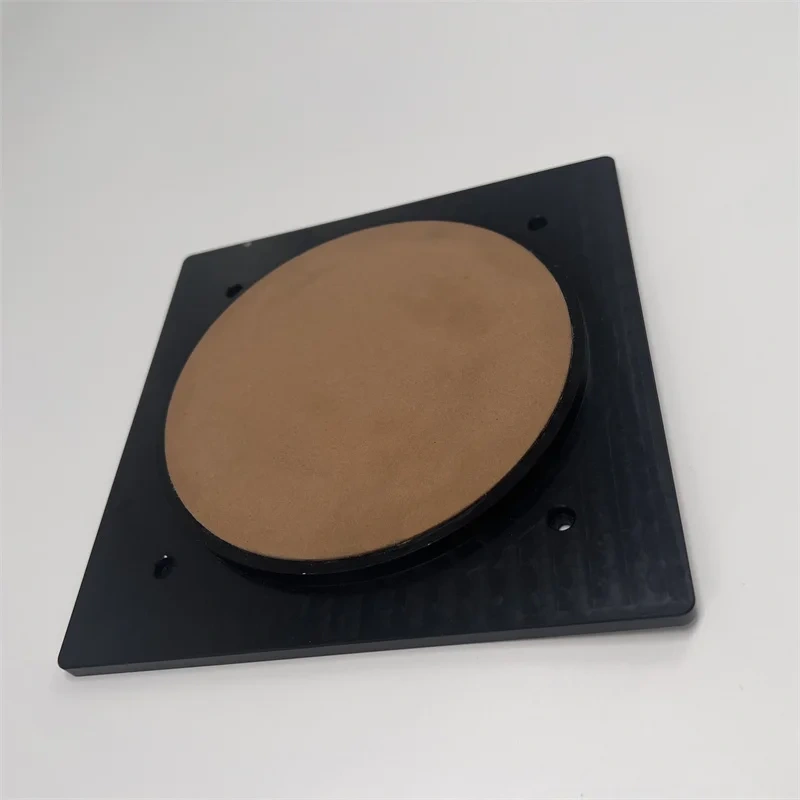

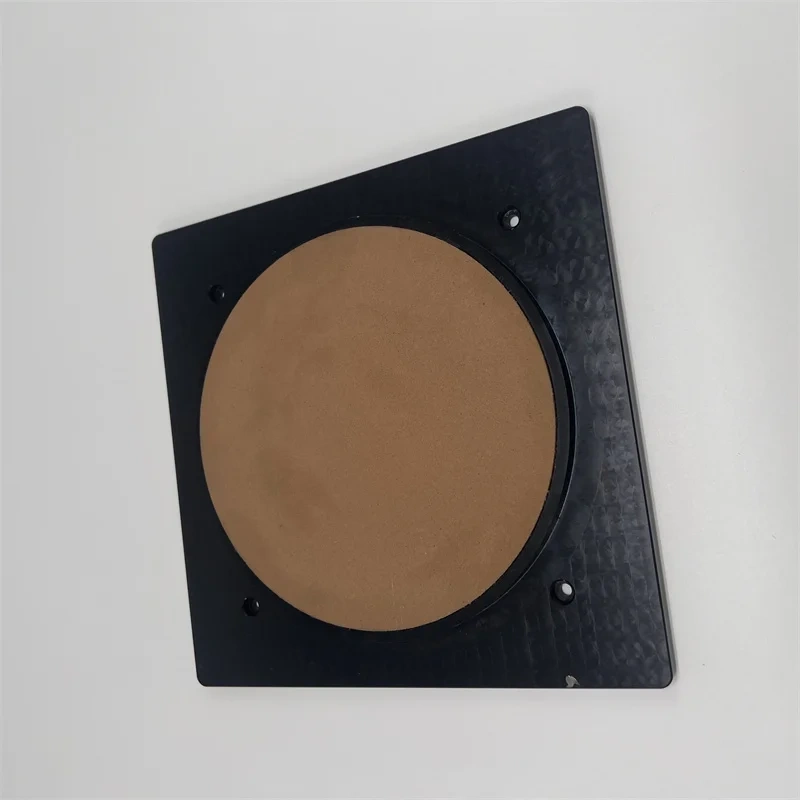

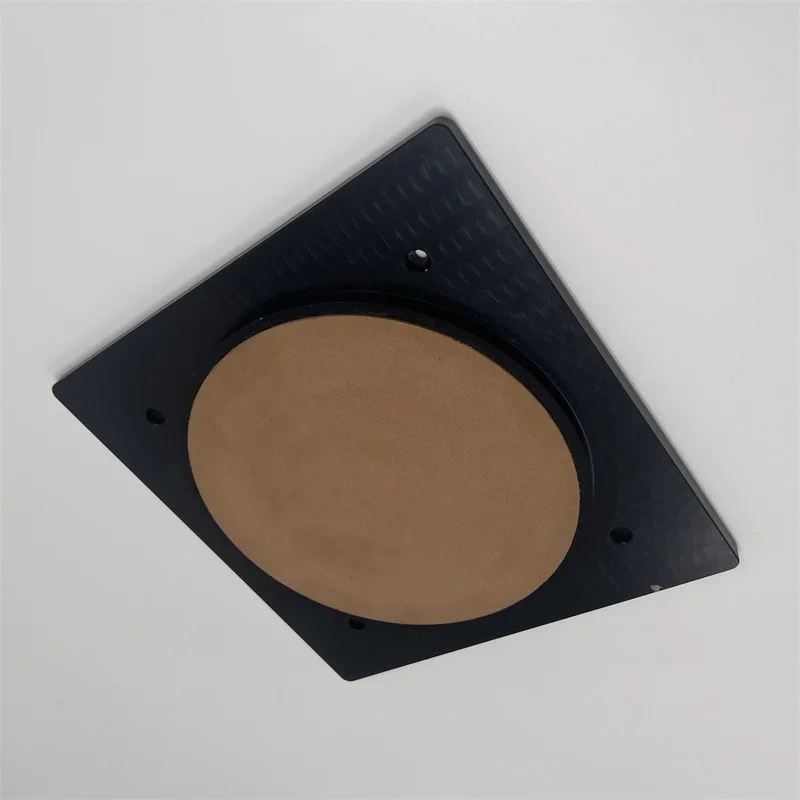

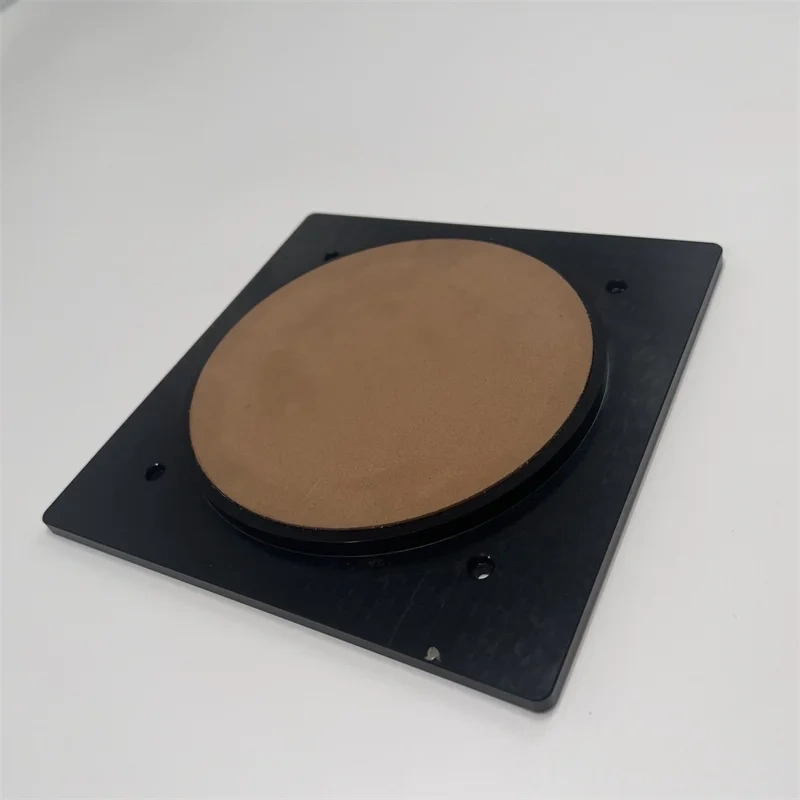

Adjustable porosity and ≤0.005mm flatness CNC Ceramic Vacuum Chuck Table Wafer for Cleaning Chucks Request a free demo today

Core Advantages

Parameter

Property |

Unit |

Porous Ceramic |

Color |

|

Brown |

Al2O3 |

wt-% |

≥80 |

SiO3 |

wt-% |

16-18 |

Density |

g/cm3 |

2.3-2.5 |

Porosity |

% |

40 |

Aperture Size |

µm |

15/30/50/100 |

Compressive Strength |

MPa |

≥600 |

Flexural Strength |

MPa |

≥400 |

Working Pressure |

MPa |

≤10 |

Hardness(HRA) |

HRA |

≥ 50 |

Acid Resistance |

mg/cm² |

≤ 10.0 |

Alkali Resistance |

mg/cm² |

≤ 2 |

Application scenarios