9F,Bldg.A Dongshengmingdu Plaza,No.21 Chaoyang East Road,Lianyungang Jiangsu,China +86-13951255589 [email protected]

Processing range up to 0.2mm thickness of the thinnest and can customize it according to your requirements.

Manufacturing Process and Workflow of RG IR RM Series Optical Glass

The production of RG IR RM Series optical glass is a highly precise and controlled sequence of operations designed to achieve specific optical properties such as refractive index, Abbe number, and high transmittance. The entire process can be broken down into the following key stages:

Advantages of RG IR RM Series Optical Glass

The primary advantages of RG IR RM Series optical glass stem from its carefully engineered chemical composition, which typically offers a balance of the following properties:

Applications of RG IR RM Series Optical Glass

Due to its advantageous properties, RG IR RM Series optical glass is widely used in various high-tech and industrial fields:

Technical specifications

|

Thickness mm |

Λtj (nm) |

Λo (nm) |

Tλo () |

k |

IR-76 |

3 |

760±10 |

850 |

83.6 |

0.6 |

RG780 |

3 |

780±10 |

900 |

83.6 |

0.5 |

IR-80 |

3 |

800±10 |

900 |

83.6 |

0.5 |

|

RG-830 IR-83 |

3 |

830±10 |

930 |

83.6 |

0.5 |

IR-85 |

3 |

850±10 |

950 |

80.0 |

0.5 |

|

Bubble |

Stripe |

Stress |

IR-76 |

C-B |

3C |

3 |

RG780 |

C-B |

3C |

3 |

IR-80 |

C-B |

3C |

3 |

|

RG-830 IR-83 |

C-B |

3C |

3 |

IR-85 |

C-B |

3C |

3 |

Customized high purity polished transparent quartz glass plate for Semiconductor

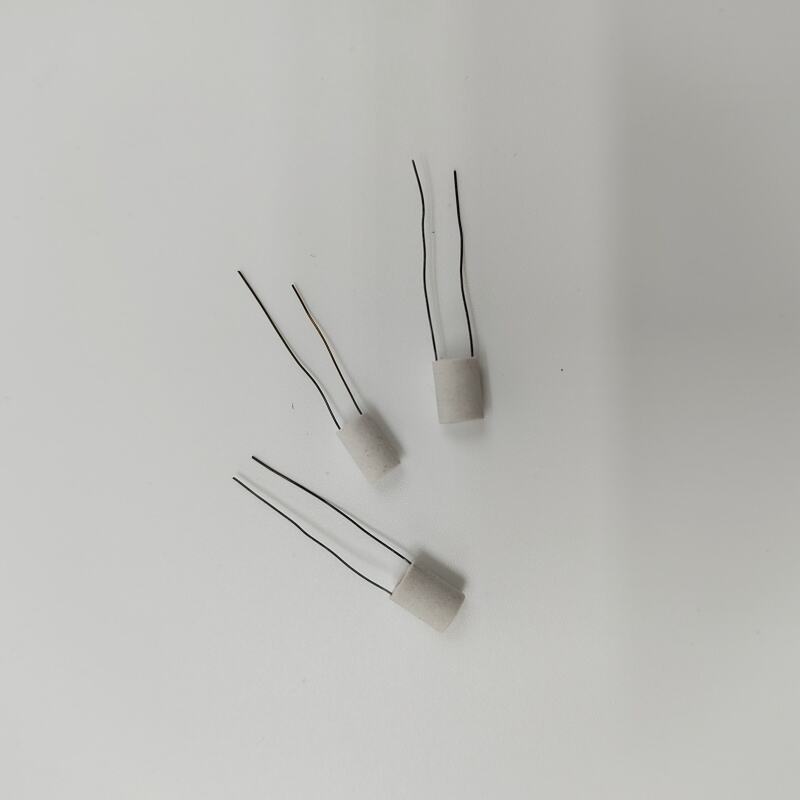

Porous Ceramic atomization Core heating element for medical and health equipment

Wooden Wick 7x73mm – High Absorption Ceramic Blended Mosquito Repellent Liquid Wick

High Purity 99% MgO Ceramic Spacers Magnesium Oxide Gasket for Thermocouple